In the process of 3D printing, due to various factors will make the drip molding shrinkage deformation, complex structure of the patterns need additional process support structure, the ladder effect of drip molding needs to take process measures to reduce and other reasons, before manufacturing entity model need to set some process measures to modify, adjust or compensate the digital model. There are two main ways to carry out the operation, one is to directly operate the CAD 3D model, the other is to modify, or adjust the scan path data, respectively described as follows.

1. Directly operate CAD 3D models

(1) Adjust the direction of the patterns during production.

(2) Expand or shrink the patterns.

(3) Make multiple patterns at the same time.

(4) Set the position of the patterns on the lifting workbench.

2. Modify or adjust scanning path data

In order to improve the forming accuracy, the three-dimensional model data can be modified and adjusted, or the scanning trajectory data of the three-dimensional section shape can be modified.

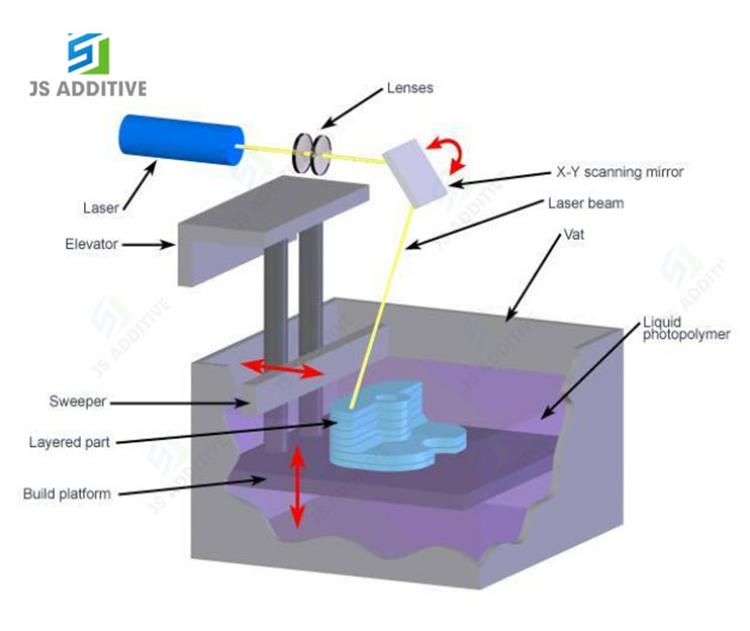

(1) Precision setting: it refers to the setting of the maximum allowable error between the section profile of the designed three-dimensional model and the actual scanning profile of the laser beam on the X-Y plane. The smaller the error, the smoother the surface of the product.

(2) Section thickness setting of patterns section: When section thickness is constant, the smaller the Angle between surface and horizontal plane, the greater the step effect. Therefore, a smaller section thickness can be set according to the direction of the model and the smaller Angle between the surface and the horizontal plane.

(3) Scanning trajectory offset: the laser beam scanning contour is larger than the design contour, so that the drip molding has a processing margin; Or make the scanning profile smaller than the design profile, so that the drip molding have a coating margin.

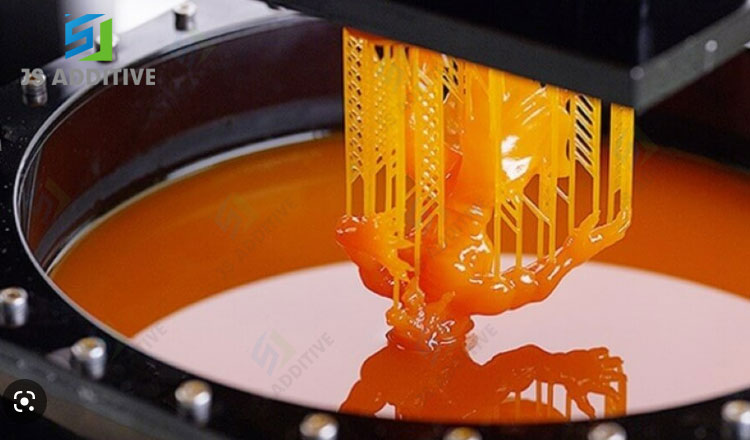

(4) Add bottom cushion support: between the forming entity model and the lifting platform need to set up a layer of bottom cushion support frame, so that the model from the lifting platform a little distance forming, so that the forming parts are not affected by the lifting platform unevenness. Underbed braces are structures that resemble thin stiffened plates so that they can be easily removed and removed from the entity model after it has been formed.

(5) Add frame and column support: when UV irradiation on the photocuring resin to cure it completely, due to the shrinkage of the curing resin, so that the parts will be deformed in the forming process, no matter what method is used to slightly fix the exposure part of the resin, can prevent the deformation of the workpieces.

(6) Selection of scan path: there are three ways for laser beam to scan a section, namely, scanning along the edge of the outer profile of the section; Scanning of internal honeycomb lattice structure except contour edges; Internal intensive fill scanning. A pattern with a complex structure can be selected, and the production process involves the three scanning modes mentioned above. Can even use a combination model including the installation of a switch, motor and so on to complete its production, in order to test the formability.

The above is to introduce how the SLA light curing 3D printer moulding process is to analyze, JSADD 3D can provides such mature SLA prototyping service. Hope to provide you with a reference.

Contributor: Vivien