The Introduction Of CNC Plastic

In CNC manufacturing, machines are operated by numerical control, in which software programs are assigned to control objects. The language behind CNC machining, also known as G code, is used to control various behaviors of the corresponding machine, such as speed, feed rate and coordination.There are many Available Materials (Plastic) in CNC Machining, Common with ABS, PMMA, PC, POM, PP, Nylon, PTFE, Bakelite, these materials can be provided to the customer to choose from JSADD 3D, Easy to quickly processing plastic parts or other products for CNC Machining technique.

Here's how it works.

Computer numerical control (CNC) machining is a manufacturing process in which pre-programmed computer software controls the operation of tools and machinery in a factory. The process can be used to control a range of complex machines, from grinders and lathes to milling machines and CNC routers. With the help of CNC machining, three-dimensional cutting tasks can be completed with only a set of prompts.Advantages

- 1.CNC has high production efficiency in the case of multi-variety and small batch production, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduces the cutting time due to the use of the best cutting amount.

- 2.The CNC machining quality is stable, the machining accuracy is high, and the repeatability is high, which is suitable for the machining requirements of aircraft.

- 3.CNC machining can process complex surfaces that are difficult to process by conventional methods, and can even process some unobservable machining parts.

Disadvantages

- High technical requirements for operators and machine maintenance personnel.

- The purchase cost of machine equipment is expensive.

Industries With CNC Machining Plastic

CNC Machining technology is widely used in all kinds of power machinery, lifting and transportation machinery, agricultural machinery, metallurgy and mining machinery, chemical machinery, textile machinery, machine tools, tools, instruments, meters and other machinery and equipment production industry.

Post Processing

For most plastic materials, here are post processing techniques that are available from JSADD 3D.

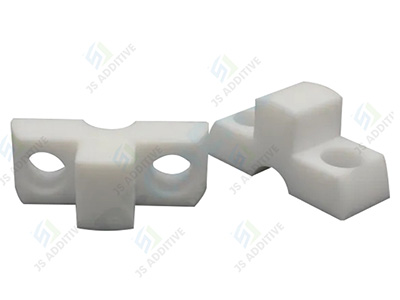

CNC Machining Plastic Materials

JSADD 3D Provide CNC Machining Plastic Materials: ABS, PMMA, PC, POM, PP, Nylon, PTFE, Bakelite.

| CNC | Model | Type | Color | Tech | Layer thickness | Features |

|

ABS | / | / | CNC | 0.005-0.05mm | Good toughness, can be bonded, can be baked to 70-80 degrees after spraying |

|

PMMA | / | / | CNC | 0.005-0.05mm | Good transparency, can be bonded, can be baked to about 65 degrees after spraying |

|

PC | / | / | CNC | 0.005-0.05mm | Temperature resistance around 120 degrees, can be bonded and sprayed |

|

POM | / | / | CNC | 0.005-0.05mm | High mechanical properties and creep resistance, excellent electrical insulation, solvent resistance and processability |

|

PP | / | / | CNC | 0.005-0.05mm | High strength and good toughness, can be sprayed |

|

Nylon | PA6 | / | CNC | 0.005-0.05mm | High strength and temperature resistance, and good toughness |

|

PTFE | / | / | CNC | 0.005-0.05mm | Excellent chemical stability, corrosion resistance, sealing, high temperature and low temperature |

|

Bakelite | / | / | CNC | 0.005-0.05mm | Excellent heat resistance, flame resistance, water resistance and insulation |

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top