JS Additive ine makore eruzivo runoshanda mu3D kudhinda masevhisi.Kuburikidza netsvagiridzo, zvakaonekwa kuti pane zvakawanda zvinokanganisa zvakananga kuumbwa kweSLA/DLP/LCD 3D kudhinda.Kuisa kukurumidza kudhinda kwakakodzera kunobatsira kuvandudza mukana wekubudirira kudhinda nekugadzira.Asi hazvisi nyore kudaro, kunyanya kune ruoko rutsva.Usati waisa kumhanya kwakakodzera kudhinda, unofanirwa kuziva kuti ndezvipi zvinhu zvinokanganisa kudhinda kweSLA/DLP/LCD 3D printers.

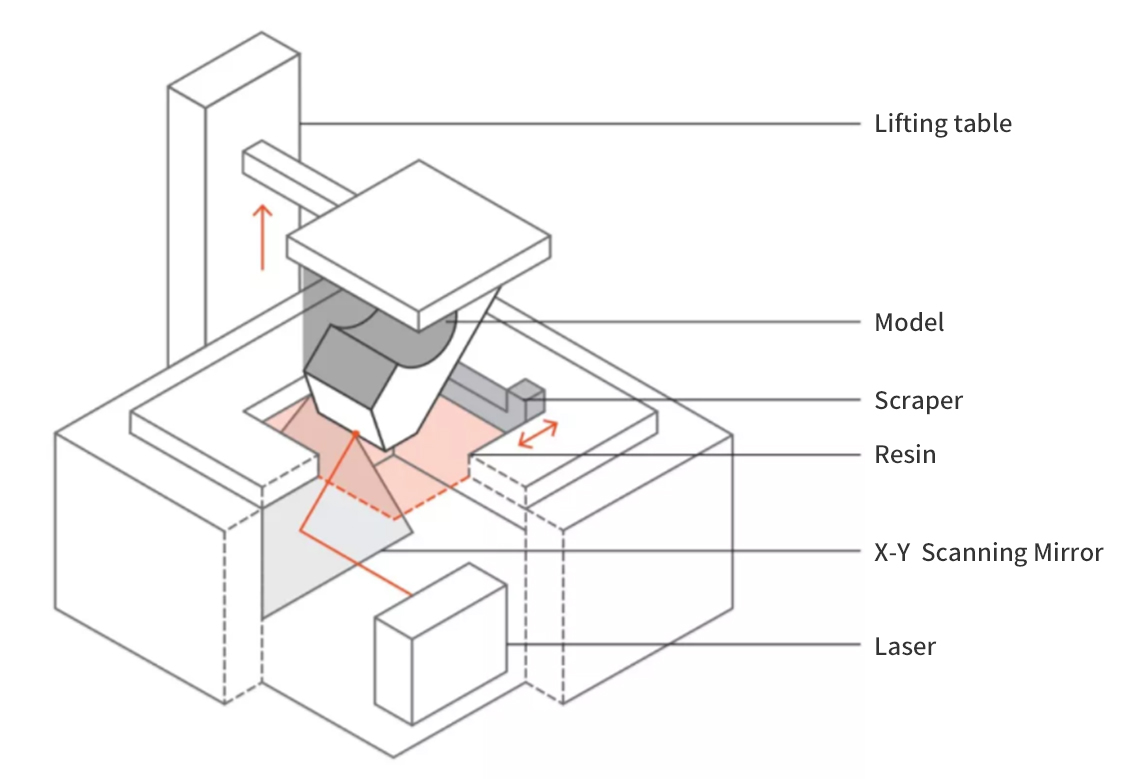

Printing Technology

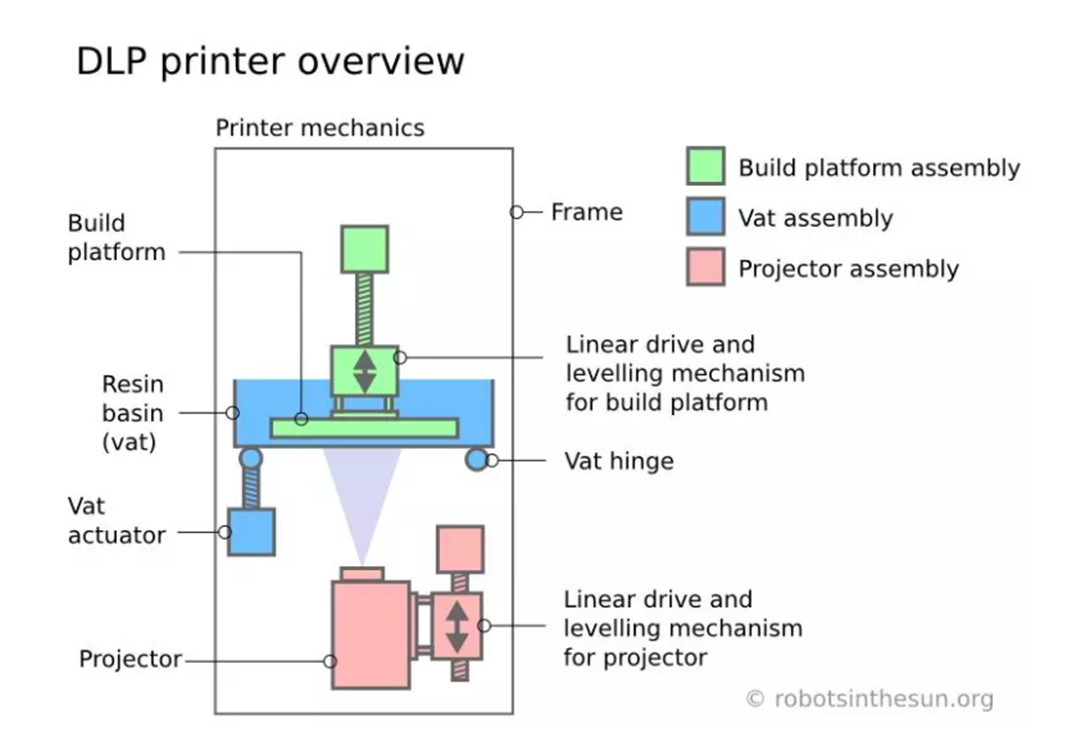

Kuenzaniswa neSLA, DLP neLCD vane mukana wakafanana, uye ndiko kumhanya kwekudhinda.Aya matekinoroji maviri ekudhinda zviri pachena ari kukurumidza.Nokuti DLP/LCD 3D printers inoumbwa pamusoro pese, iyo inoumbwa nekutsvaira, kusiyana neSLA, iyo inoumbwa ne laser dots.

DLP printer chimiro Mufananidzo sosi: robotsinthesun.org

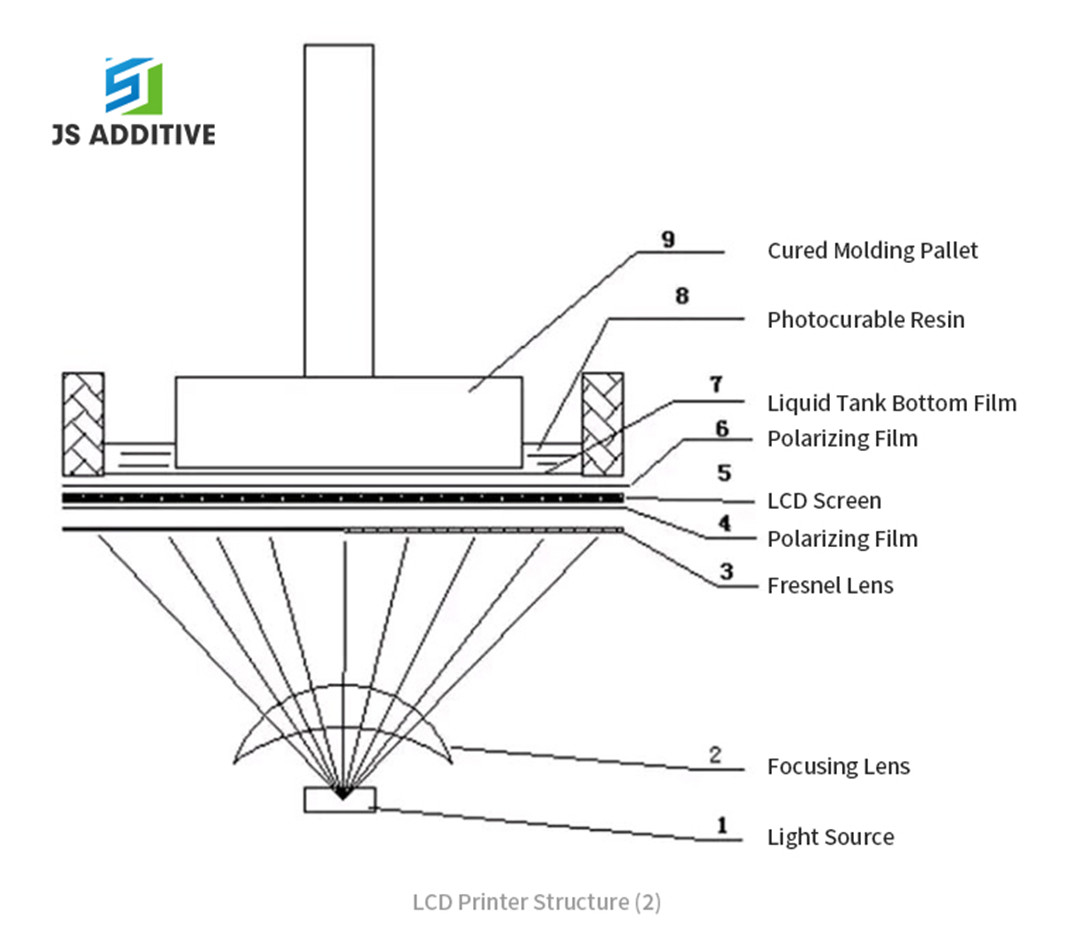

LCD printer chimiro 1 chiedza chitubu 2 chinotarisa lens 3 Fresnel lens 4 polarizing firimu 5 LCD skrini 6 polarizing firimu 7 mvura tangi pasi firimu 8 photocurable resin 9 yakarapwa molding pallet

Printer Settings

Kana iyo yekudhinda kumhanya ikaiswa pachine nguva, haizombopfuuri kukosha kwakaiswa.

Chimwe chinhu chine chekuita nekumhanya kwekudhinda ndiko kumhanya uko system inodhinda dhizaini imwe chete.Pakudhinda, sosi yemwenje inopfuura nepazasi pedhishi resin inoonekera, uye resin ichangobva kuporeswa inoda kufinha-kubvisa maitiro usati waenderera mberi nekurapa mutsva.Vamwe vagadziri vanoita kuti sisitimu iende kuburikidza nekuita peeling nekukurumidza kuti iwedzere kumhanya kwekudhinda.Imwe nzira yekubvisa dambudziko iri kurapa kumusoro kweresin level, kwete pasi.

Kusimba kweChiedza Chinobva

Kudhinda resin kunoshandisa mwenje sosi kurapa photosensitive fluid resin kugadzira yekupedzisira 3D modhi.

Musiyano uripo pakati peaya matatu matekiniki ndiwo mwenje sosi inoshandiswa kurapa resin.

Kusimba kwechiedza chinoshandiswa kunogona kukanganisa kumhanya kweprinta.Tinogona kuivandudza nekuwedzera kusimba kwechiedza, asi izvo zvinorevawo mari yakawedzerwa.

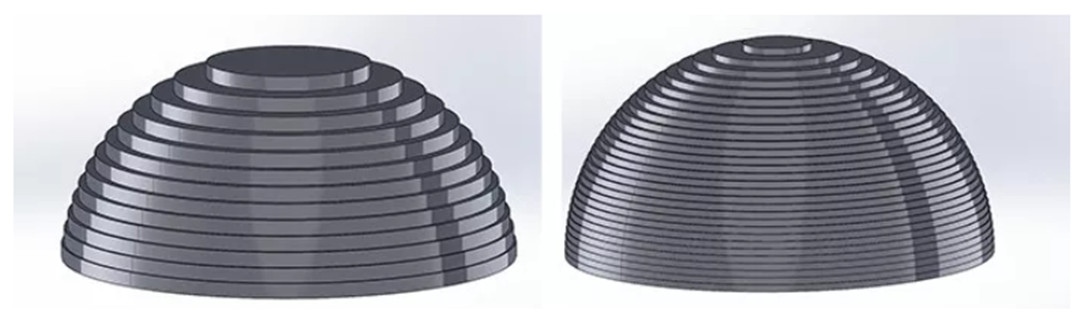

LayerThickness

Layer ukobvu kunokanganisa kukurumidza kudhinda uye mhando yemhando.Ukobvu hunodiwa kudhinda modhi inosarudza kumhanya kwekudhinda uye nguva yainotora.Iyo yakatetepa kukora kwe layer, iyo nguva yakawanda ichatora kudhinda 3D modhi yehurefu hwakafanana.Nekuti hurefu hwakazara hunoramba hwakafanana, iyo yakaonda iyo iyo dhizaini ukobvu, iyo yakawanda layers iyo printer inoda kudhinda, uye nguva yakawanda yainotora.Asi zvishoma, iyo yakaonda iyo yakakura ye layer, iyo yakakwirira yemhando yechigadzirwa chakapedzwa.

Kuruboshwe-75µm Pixel

Kurudyi-37µm Pixel

Material

Iko kumhanyisa kwekudhinda kwe3D printer zvakare kunoenderana nerudzi rwezvinhu.Resins akasanganiswa akasiyana monomers, prepolymers, photoinitiators, uye zvimwe zvakasiyana-siyana zvekuwedzera zvine zvimiro zvakasiyana uye dzakasiyana nguva dzekurapa.

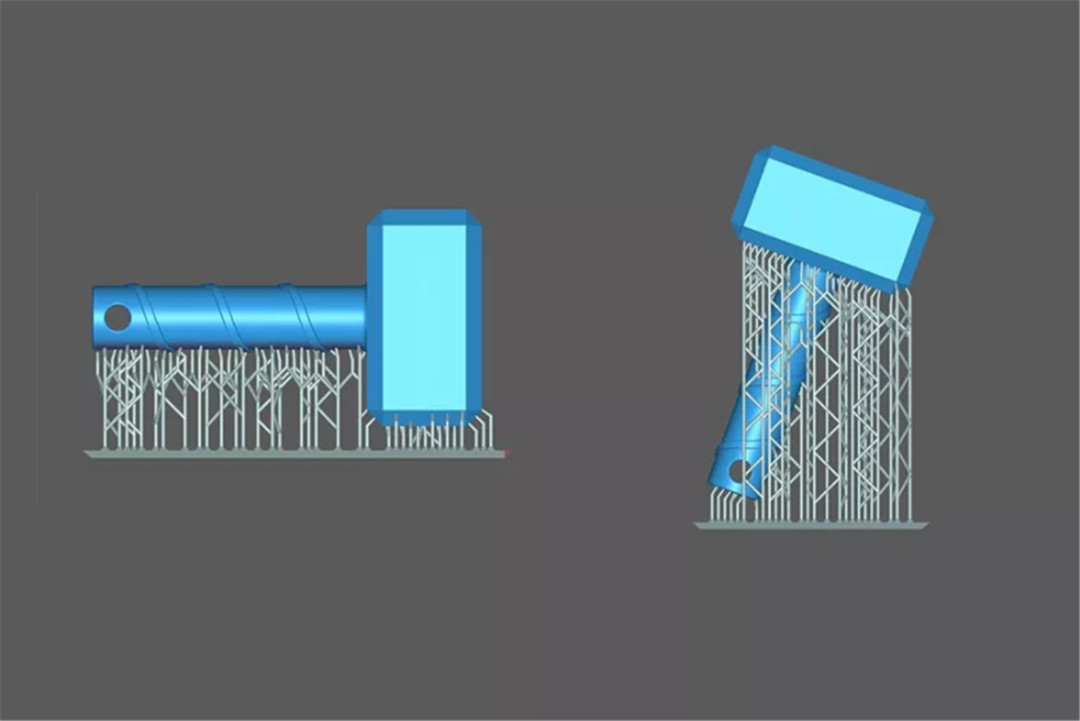

Chimiro uye Kuiswa kweMuenzaniso

Chimiro chemuenzaniso chinokanganisawo kumhanya kwekudhinda.Kana iyo modhi yakavharwa uye isina ruzivo rwakaoma kunzwisisa, kudhinda kunokurumidza.Kuiswa kunonzwisisika kwemuenzaniso kuchakanganisawo kumhanya kwekudhinda.Kazhinji, zvichange zvichikurumidza kuisa modhi yakatwasuka pane yakatwasuka kana ichidhinda, asi iko kurongeka kunogona kuderedzwa.

Izvi ndizvo zvinhu zvikuru zvinokanganisa kumhanya kwekudhinda pakati pe 3D kudhinda.Mukuita kwekuwedzera kwekugadzira, mamiriro chaiwo anogona kunge akaoma kupfuura izvozvo.Naizvozvo, kumhanya kwekudhinda kuri kutengeserana.Kamwe kumhanya kwekudhinda kunowedzera, zvinokwanisika kuti mhando yekudhinda ichadzikira.Nzira yekuyera sei zvayakanakira nezvayakaipira zvinodawo kusarudzwa zvinoenderana nemamiriro chaiwo.