JSADD 3D has years of practical experience in the 3D printing services. Through research, it was found that there are many factors directly affecting the molding speed of SLA/DLP/LCD 3D printing. Setting a suitable printing speed is helpful to improve the probability of successful printing and manufacturing efficiency. But it is not that easy, especially for new hand. Before setting suitable printing speed, you need to know what factors affect the printing speed of SLA/DLP/LCD 3D printers.

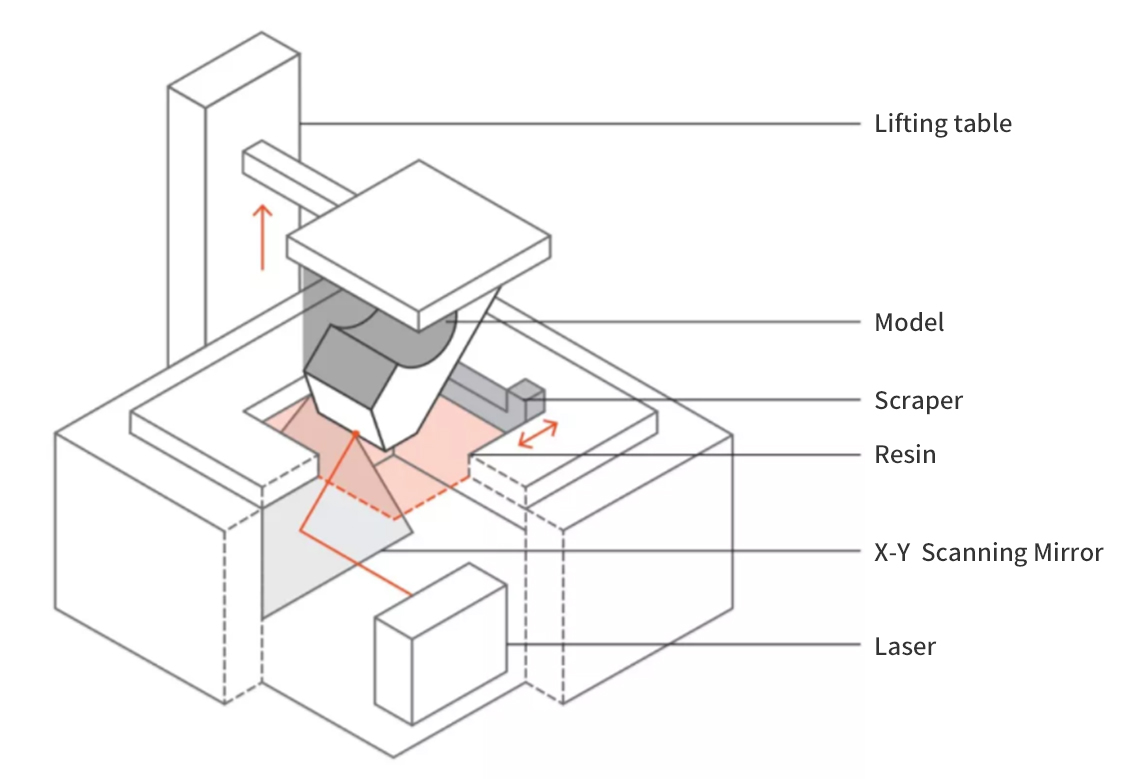

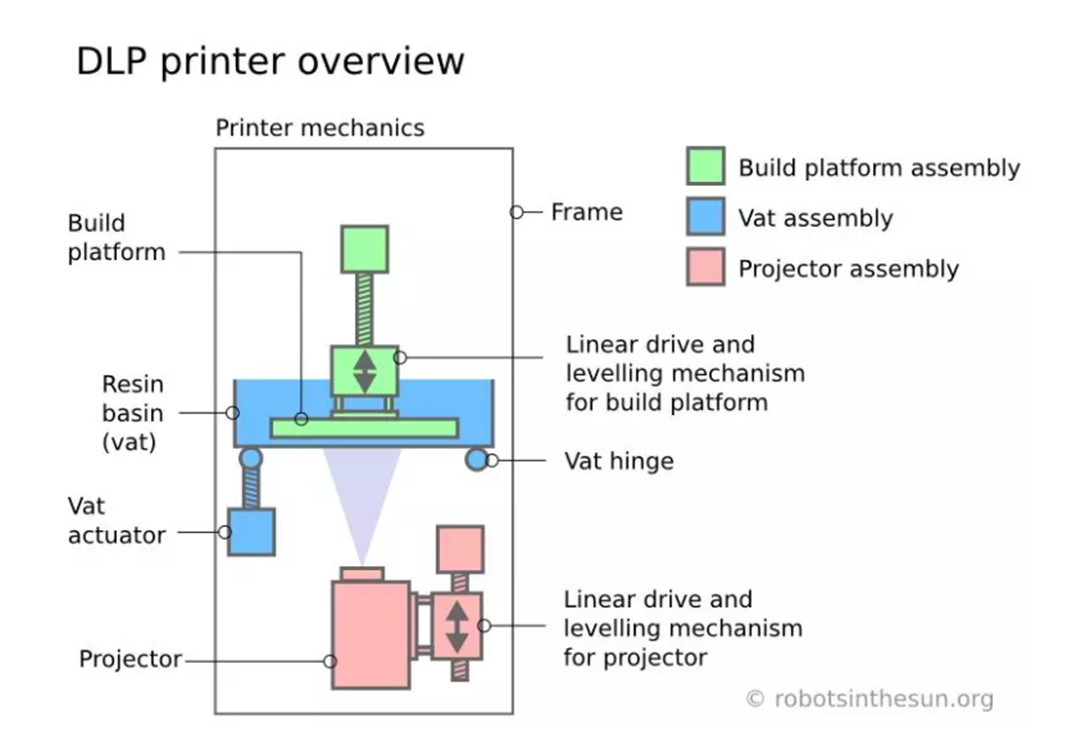

Printing Technology

Compared to SLA, DLP and LCD have the same advantage, and that is printing speed. These two printing technologies are obviously faster. Because DLP/LCD 3D printers are formed on the whole surface, which is formed by sweeping, unlike SLA, which is formed by laser dots.

DLP printer structure Image source: robotsinthesun.org

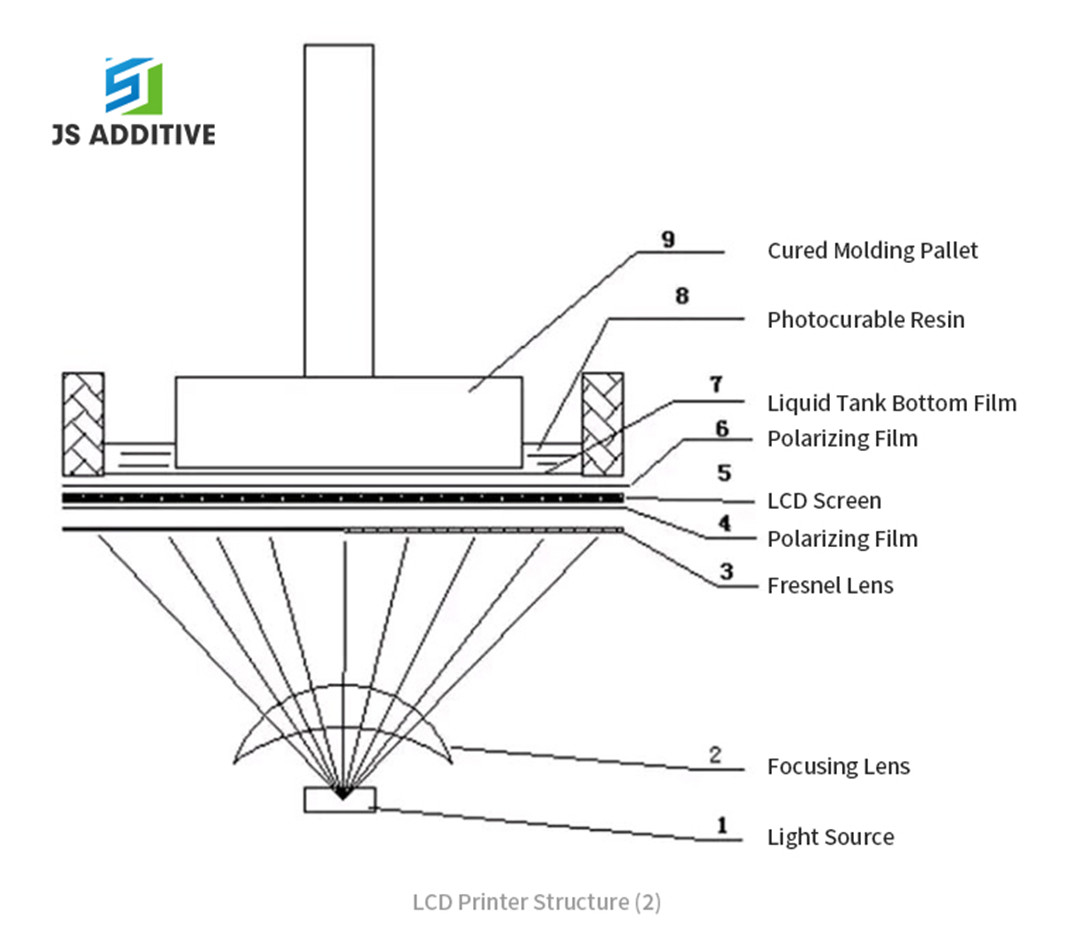

LCD printer structure 1 light source 2 focusing lens 3 Fresnel lens 4 polarizing film 5 LCD screen 6 polarizing film 7 liquid tank bottom film 8 photocurable resin 9 cured molding pallet

Printer Settings

If the print speed is set in advance, it will never exceed the set value.

Another factor related to print speed is the speed at which the system prints a single layer. When printing, the light source passes through the bottom of the transparent resin trough, and the freshly cured resin requires a tedious peel-off process before continuing to cure a new layer. Some manufacturers make the system go through the peeling process quickly to increase printing speed. Another way to eliminate this hassle is to cure at the top of the resin level, not the bottom.

The Intensity of Light Source

Resin printing uses a light source to cure a photosensitive liquid resin to create the final 3D model.

The difference between the three techniques is the light source used to cure the resin.

The intensity of the light source used can affect the printing speed of the printer. We can improve it by increasing the light intensity, but that also means extra cost.

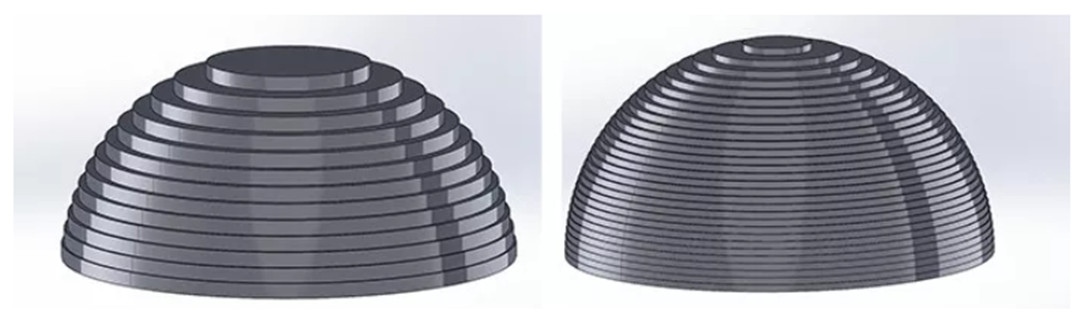

Layer Thickness

Layer thickness affects both printing speed and model quality. The layer thickness required to print the model determines the printing speed and the time it takes. The thinner the layer thickness, the more time it will take to print a 3D model of the same height. Because the total height remains the same, the thinner the layer thickness, the more layers the printer needs to print, and the more time it takes. But relatively, the thinner the layer thickness, the higher the quality of the finished product.

Left-75µm Pixel

Right-37µm Pixel

Material

The printing speed of the 3D printer also depends on the type of materials. Resins combinated of different monomers, prepolymers, photoinitiators, and various other additives have different properties and different cure times.

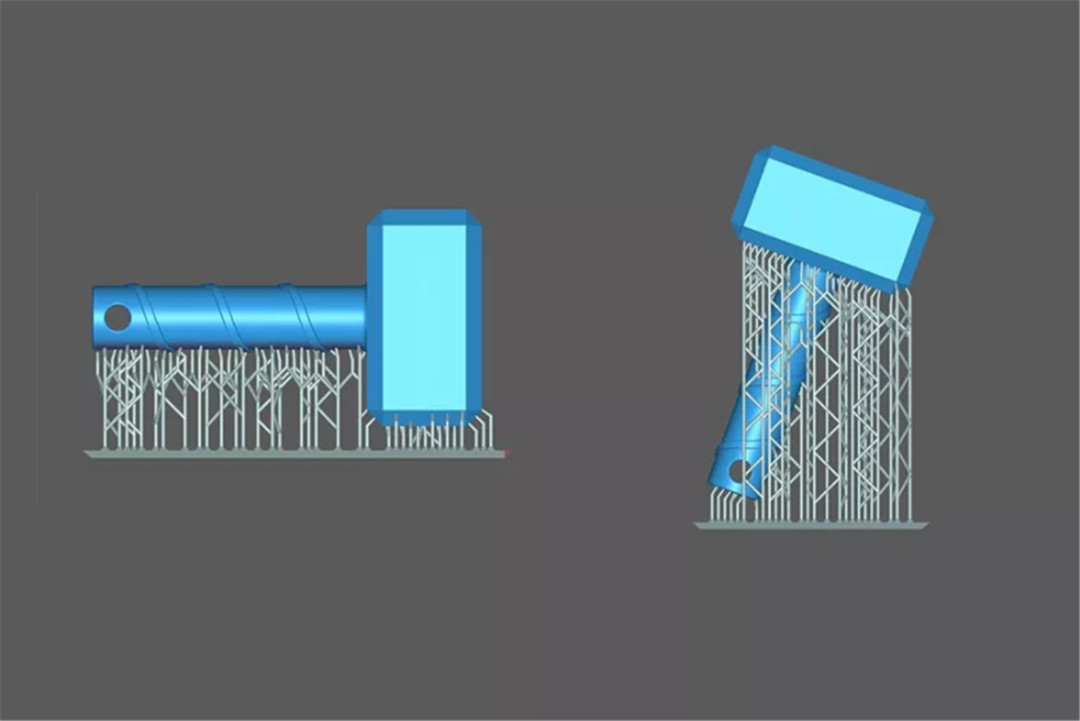

The Structure and Placement of Model

The structure of the model also affects the printing speed. If the model is hollowed out and has no intricate details, printing is much faster. The reasonable placement of the model will also affect the printing speed. In general, it will be much faster to place the model horizontally than vertically when printing, but the accuracy may be reduced.

These are the main factors that affect the printing speed among 3D printing. In the process of additive manufacturing, the actual situation may be more complicated than that. Therefore, printing speed is a trade-off. Once the printing speed increases, it is likely that the print quality will decrease. How to weigh the pros and cons also needs to be decided according to the actual situation.