SLS (Selective Laser Sintering) printing was invented by C.R. Decherd of the University of Texas at Austin.It is one of the 3D printing technologies with the most complex forming principles, the highest conditions, and the highest cost of equipment and material. However, it is still the most far-reaching technology to the development of 3D printing technology.

SLS printing is similar to SLA printing in that you need to use lasers to solidify the entire substance.The difference is that infrared laser beam will be used in SLS printing, and the material is not the photopolymer resin but the combined material, such as plastic, wax, ceramic, metal powder, and nylon powder.

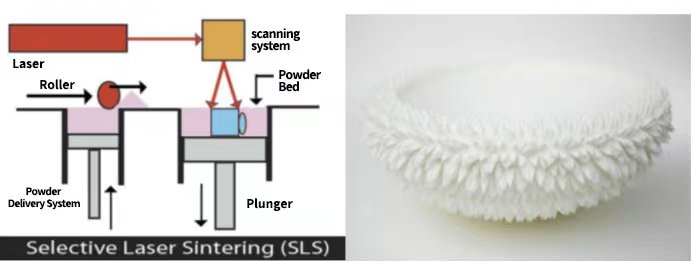

>>How It Works

The powder material is sintered layer by layer at high temperature under laser irradiation, and the computer controls the light source positioning device to achieve precise positioning. By repeating the process of laying out powder and melting where needed, the parts are built up in the powder bed.

>>Comparison of Advantages and Disadvantages

Advantages:

Suitable for complex mechanisms and special geometric parts

Supports small batch/customized production

Strong toughness, good hardness, no extra support, short processing period, and low cost

Disadvantages:

The surface quality of SLS printing is not as good as that of SLA resin 3D printing

High equipment costs and maintenance costs

>>Optional materials

l Nylon White/Grey/Black PA12

Performance:

Strong toughness and good hardness

It can be processed and assembled twice.

>>Industries With SLS 3D Printing

Functional testing, such as prototype processing for appearance or R&D design

Small batch/customized production, including customized gifts

Suitable for industries that require precision and complex mechanisms, such as aerospace, medical, mold, 3D printing surgical guides, etc.

Contributor: Daisy