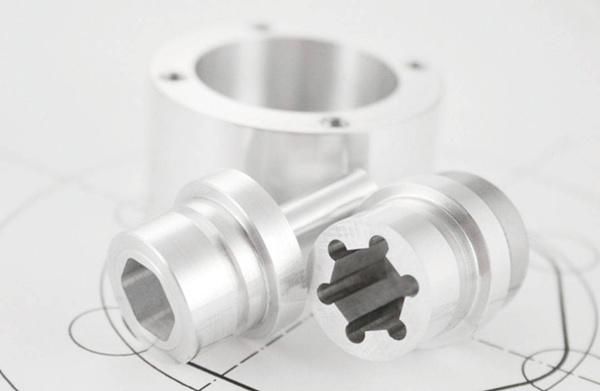

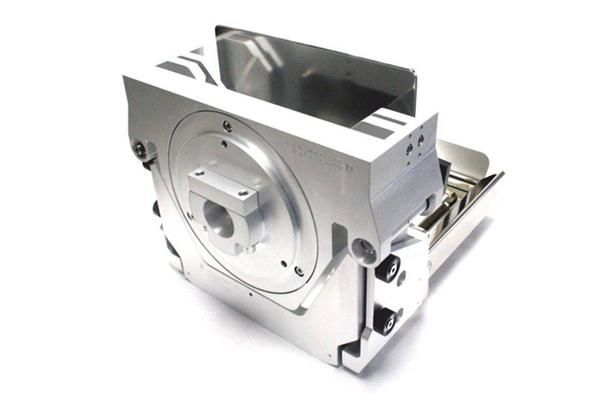

CNC processing usually refers to the computer digital control precision machining, CNC processing lathe, CNC processing milling machine, CNC machining boring and milling machine, etc.

In addition to providing 3D printing services for users, it can also provide laser cutting, silicone compound molding, and CNC processing and other services, among which the main metal materials for CNC processing are the following:

1, aluminum alloy 6061

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment pre-stretching process. Although its strength is not compared with 2XXX series or 7XXX series, it has more magnesium and silicon alloy characteristics.

Material advantages:

It has excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness and no deformation after processing, material density without defects and easy polishing, easy color film, excellent oxidation effect and other excellent characteristics.

2,7075 aluminum alloy

7075 Aluminum alloy is a kind of cold treatment forging alloy, high strength, far better than soft steel.7075 is one of the most powerful commercially available alloys.

Material advantages:

Common corrosion resistance, good mechanical properties and anode reaction. Fine grains make deep drilling performance better, tool wear resistance enhanced, and thread rolling more distinctive.

3. Copper

Pure copper (also known as copper) is a tough metal with excellent conductivity in rose red. It is not pure copper, it contains 99.9% copper, and adds some other elements to improve the surface and performance.

Material advantages:

It has good electrical conductivity, thermal conductivity, ductility, deep impact and corrosion resistance.

The electrical conductivity and thermal conductivity of purple copper is second only to silver, which is widely used in the production of conductive and thermal conductivity equipment. Copper has good corrosion resistance in the atmosphere, seawater and some non-oxidizing acid (hydrochloric acid, dilute sulfuric acid), alkali, salt solution and a variety of organic acids (acetic acid, citric acid), and is used in the chemical industry.

Good weldability, can be cold, thermoplastic processing into a variety of semi-finished products and finished products. In the 1970s, purple copper production exceeded the total output of all other types of copper alloys.

4.Brass

Brass is a copper and zinc alloy, and the brass composed of copper and zinc is called ordinary brass.

Material advantages:

It has high strength, high hardness and strong chemical corrosion resistance. The mechanical performance of cutting processing is also more outstanding.

Brass has a strong wear-resistance performance. Special brass, also known as special brass, has high strength, high hardness and strong chemical corrosion resistance. The mechanical performance of cutting processing is also more outstanding. The seamless copper tube pulled by brass is soft and has strong wear resistance.

5.45 steel

45 Steel is the name of GB, also called “oil steel”, the steel has a higher strength and a better cutting processing.

Material advantages:

With high strength and good cutting and processing, after the appropriate heat treatment can obtain a certain toughness, plasticity and wear resistance, convenient material source, suitable for hydrogen welding and argon arc welding.

6.40 Cr steel introduction

40 Cr is the standard steel number of GB in China, and 40 Cr steel is one of the most widely used steels in the machinery manufacturing industry.

Material advantages:

Good comprehensive mechanical properties, good low-temperature impact toughness and low notch sensitivity. Steel has good quenability, which is suitable for cyanide and high frequency quenching treatment in addition to quality treatment. The cutting performance is better.

7.Q235 steel introduction

The Q235 steel is a carbon structural steel, and the Q in its steel number represents the yield strength. Usually, the steel is used directly without heat treatment.

Material advantages:

With the increase of the thickness of the material, the yield value will be reduced, due to the moderate carbon content, the comprehensive performance is good, the strength, plasticity and welding properties are better matched, the most widely used.

8.SUS304 Steel

SUS304 Refers to the 304 stainless steel, with good processing performance, high toughness characteristics, stainless steel 303 can also be processed

Material advantages:

Good corrosion resistance, heat resistance, corrosion resistance, low temperature strength and mechanical properties, good stamping and bending of thermal processing, no heat treatment hardening phenomenon, no magnetism.