Advantages

Excellent chemical resistance

Good functionality and mechanical properties

Good waterproof performance

Ideal Applications

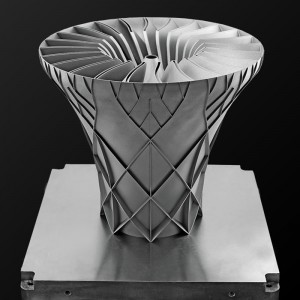

Aerospace

Household electronic

Automobile

Medical assistance

Art and craft

Architecture

Technical Data-sheet

| Category | Measurement | Value | Method |

| General properties | Powder melting point (DSC) | 187 °C/369 °F | ASTM D3418 |

| Particle size | 60 µm | ASTM D3451 | |

| Bulk density of powder | 0.425 g/cm3 | ASTM D1895 | |

| Density of parts | 1.01 g/cm3 | ASTM D792 | |

| Mechanical properties | Tensile strength, max load9 , XYTensile strength, max load9 , Z

Tensile modulus9 , XY Tensile modulus9 , Z Elongation at break9 , XY Elongation at break9 , Z Flexural strength (@ 5%)10 , XY Flexural strength (@ 5%)10 , Z Flexural modulus10 , XY Flexural modulus10 , Z Izod impact notched (@ 3.2 mm, 23ºC), XYZ |

48 MPa/6960 psi | ASTM D638 |

| Thermal properties | Heat deflection temperature (@ 0.45 MPa, 66 psi), XYHeat deflection temperature (@ 0.45 MPa, 66 psi), Z

Heat deflection temperature (@ 1.82 MPa, 264 psi), XY Heat deflection temperature (@ 1.82 MPa, 264 psi),Z |

48 MPa/6960 psi | ASTM D638 |

| 1700 MPa/247 ksi | ASTM D638 | ||

| 1800 MPa/261 ksi | ASTM D638 | ||

| 20% | ASTM D638 | ||

| 15% | ASTM D638 | ||

| 65 MPa/9425 psi | ASTM D790 | ||

| 70 MPa/10150 psi | ASTM D790 | ||

| 1730 MPa/251 ksi | ASTM D790 | ||

| 1730 MPa/251 ksi | ASTM D790 | ||

| 3.5 kJ/m2 | ASTM D256 Test Method A | ||

| 175 ºC/347 ºF | ASTM D648 Test Method A | ||

| 175 ºC/347 ºF | ASTM D648 Test Method A | ||

| 95 ºC/203 ºF | ASTM D648 Test Method A | ||

| 106 ºC/223 ºF | ASTM D648 Test Method A | ||

| Recyclability | Refresh ratio for stable performance | 20% | |

| Certifications | USP Class I-VI and US FDA guidance for Intact Skin Surface Devices, RoHS11, EU REACH, PAHs | ||