Kenyelletso ea CNC Machining (Metal)

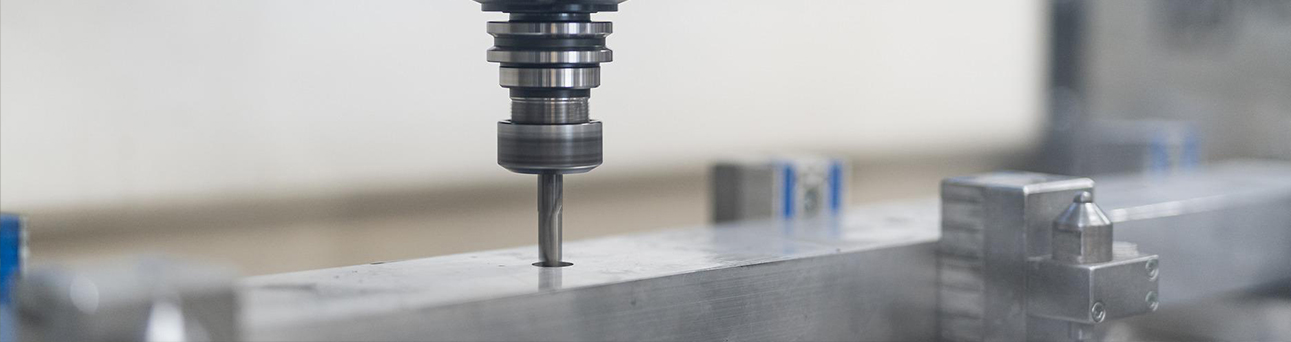

CNC Machining Metal ke tšebeliso ea lisebelisoa tsa mochine oa ho laola lipalo ho sebetsa tšepe joalo-joalo, e boetse e bua ka tšebeliso ea lisebelisoa tsa ho laola lipalo.Lisebelisoa tsa mochini oa CNC li hlophisitsoe ebile li laoloa ke puo ea taolo ea lipalo, hangata G khoutu.Puo ea khoutu ea G ea machining ea CNC e bolella lihokahanyo tsa boemo ba Cartesian tse sebelisoang ke sesebelisoa sa mochini oa NC, le ho laola lebelo la phepelo ea sesebelisoa le lebelo la spindle, hammoho le mesebetsi ea sesebelisoa sa converter le se pholisang.Mechine ea ho laola lipalo e na le melemo e meholo ho feta mochini oa matsoho.

Mona ke kamoo e sebetsang kateng.

Ha CNC Metal e sa tsoa qala, ho tsosolosoa ha li-axis tse tharo ho lokela ho etsoa ho hlahloba hore na oli ea terene ea tataiso le oli ea spindle hydraulic ea mochine li lekane.

Ha hoa lekana ho tlatsa mafura ka nako.Boholo ba mosebetsi oa ho sebetsa o lokela ho lumellana le litšoantšo, esita le haeba ho na le lekhalo le lenyenyane feela le lokelang ho botsa tsamaiso e ka holimo kapa lenaneo.

Ka tshebetso ya ho sebetsa lenaneo e robehile kahoo ha lenaneo le boetse le le tšekamelo ea ho phoso, lokela ho hlahloba ka nako.Axis ea XYZ e lokela ho tlosoa ka nako e le 'ngoe ha sesebelisoa se lokela ho fetoloa ha se sebetsa.

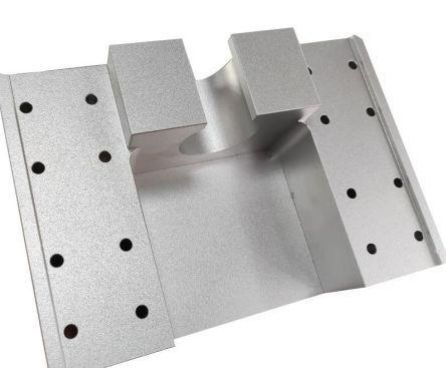

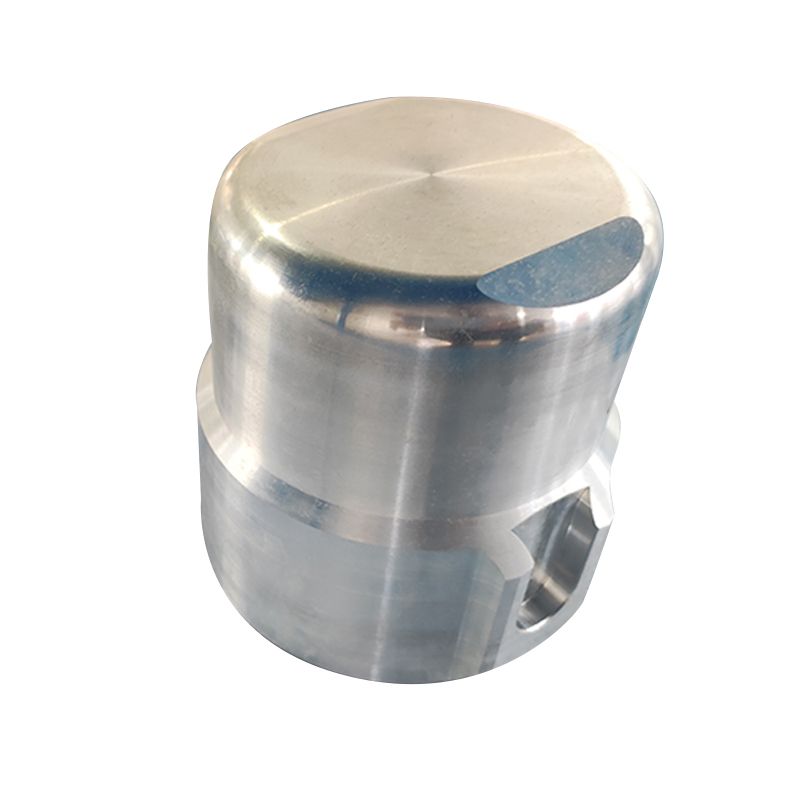

Mohlala oa ts'ebetso e akaretsang haholo-holo o kenyelletsa ho nepahala ha lesoba la phini, lesoba la phini ea tataiso, groove ea ho kenya, ho slotting, jj.

Habonolo ka ho sebetsa ho itšeha thipa: ena ke phihlelo ea ho sebetsa mochine, ba qalang ka 'na ba se ke ua nahana ka lintlha tsena, kaha phihlelo re lokela ho hopola hore ile a kopana le ho sebetsa sebakeng se tšoanang tlhokomelo ea bona.

Melemo

- 1.Ts'ebetso e bonolo ho etsa lenaneo 'me e ka hlahisa likarolo tse nang le geometry e bonolo, ka ho nepahala ho phahameng.

- 2.E na le bokhoni bo phahameng ba tlhahiso.

- 3.Litšenyehelo tsa ho etsa mechine ka karolo e itseng li batla li le tlaase.

- Limililo tsa 4.3-axis CNC li theko e tlase ho feta balekane ba tsona ba 5-axis.

Mefokolo

- Litlhoko tse phahameng tsa tekheniki bakeng sa basebetsi le basebetsi ba tlhokomelo ea mochini.

- Theko ea theko ea thepa ea mochini e theko e boima.

Liindasteri tse nang le CNC Machining Metal

● ABS: E tšoeu, e mosehla o khanyang, e ntšo, e khubelu.● PA: E tšoeu, e mosehla o khanyang, e ntšo, e putsoa, e tala.● PC: E bonaletsang, e ntšo.● PP: E tšoeu, e ntšo.● POM: E tšoeu, e ntšo, e tala, e thokoa, e tšehla, e khubelu, e putsoa, ea lamunu.

Post Processing

Bakeng sa lisebelisoa tse ngata tsa tšepe, mona ke mekhoa ea ho sebetsa ka poso e fumanehang ho tsoa ho JS Additive.

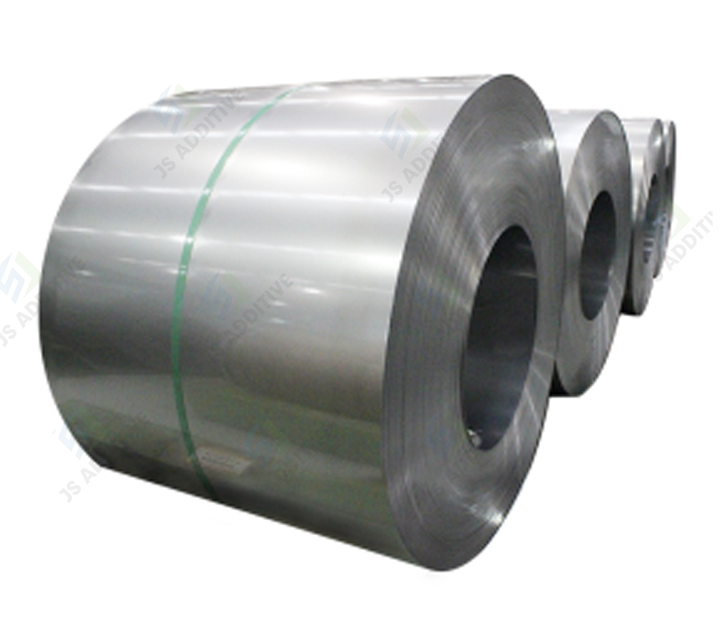

CNC Machining Metal Materials

JS Additive Fana ka CNC Machining Metal Materials: Aluminium Alloy, Brass, S45C, Q235 Steel, Sainless Steel, Titanium Alloy, D2 Steel, Magnesium Alloy

Ts'ebeletso e ntle ka ho fetisisa ea CNC Machining Metal Technique ho tsoa ho JS Additive.