Ukwethulwa kweCNC Machining (Metal)

I-CNC Machining Metal ukusetshenziswa kwamathuluzi omshini wokulawula izinombolo ukucubungula insimbi nokunye, futhi ibhekisela ekusetshenzisweni kwamathuluzi omshini wokulawula izinombolo.Amathuluzi omshini wokuchasisa we-CNC ahlelwa futhi alawulwa ngolimi lokulawula izinombolo, ngokuvamile ikhodi ye-G.Ulimi lwekhodi ye-G lomshini we-CNC lutshela izixhumanisi ze-Cartesian ezisetshenziswa ithuluzi lomshini lamathuluzi omshini we-NC, futhi lilawula isivinini sokuphakelayo sethuluzi nesivinini sokuphotha, kanye nemisebenzi yesiguquli samathuluzi nesipholile.Imishini yokulawula izinombolo inezinzuzo ezinhle ngaphezu komshini wezandla.

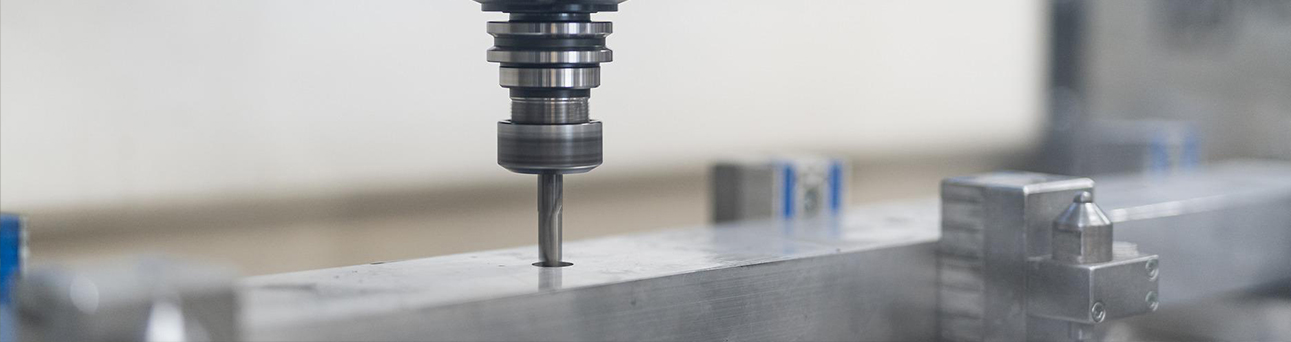

Nansi indlela esebenza ngayo.

Lapho i-CNC Metal isanda kuqaliswa, ukubuyiselwa kwemvelaphi yama-eksisi amathathu kufanele kwenziwe ukuze kubhekwe ukuthi uwoyela wesitimela esiqondisayo kanye nowoyela we-spindle hydraulic womshini anele yini.

Akwanele ukugcwalisa i-refueling ngesikhathi.Usayizi we-workpiece yokucubungula kufanele uhambisane nemidwebo, ngisho noma igebe elincane kufanele libuze abaphathi abangenhla noma uhlelo.

In the inqubo processing uhlelo ephukile ngakho lapho uhlelo futhi ethambekele iphutha, kumele ihlolwe ngesikhathi.I-eksisi ye-XYZ kufanele ikhishwe ngesikhathi esifanayo njengoba ithuluzi kufanele lishintshwe ekucubunguleni.

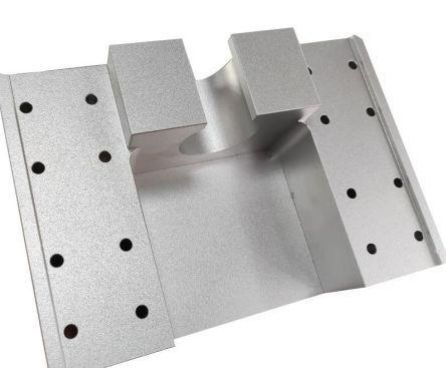

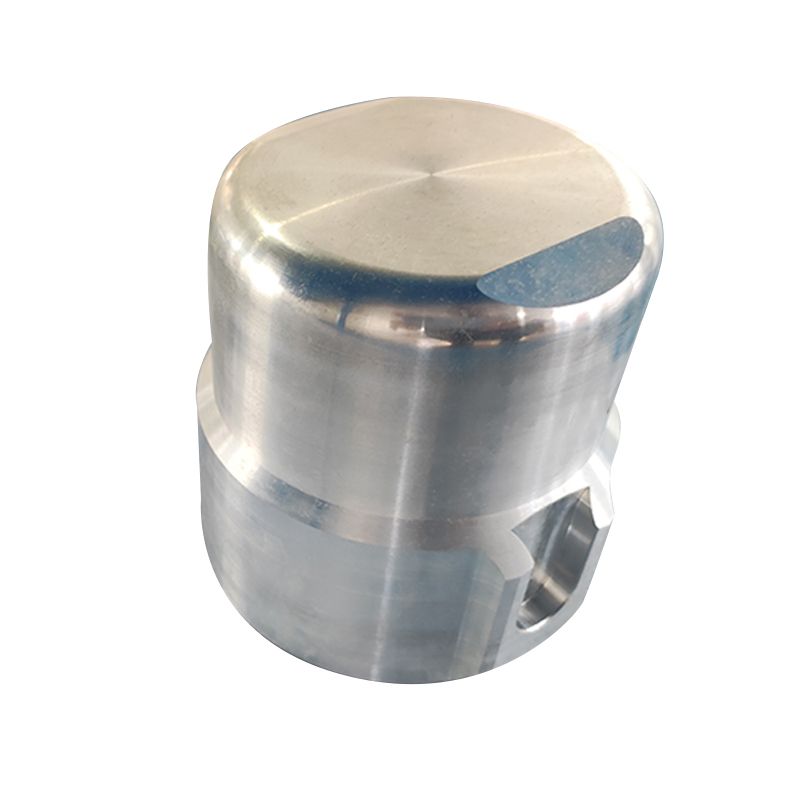

Isibonelo sokucutshungulwa okujwayelekile ikakhulukazi sihlanganisa ukunemba kwembobo yephini, imbobo yephinikhodi, i-groove yokufaka, i-slotting, njll.

Kalula ekucubunguleni ummese wokusika: lokhu kuyisipiliyoni somshini wokusebenza, abaqalayo bangase bangacabangi lezi zici, njengoba isipiliyoni kufanele sikhumbule ukuthi esihlangabezane nakho ekucubunguleni indawo efanayo ukunaka kwabo.

Izinzuzo

- I-1.Inqubo kulula ukuyihlela futhi ingakhiqiza izingxenye nge-geometry elula, ngokunemba okuphezulu.

- I-2.Inamandla okukhiqiza aphezulu.

- I-3.Izindleko zokukhiqiza ingxenye ngayinye ziphansi.

- Izigayo ze-CNC ze-4.3-eksisi zibiza kancane kunozakwabo we-5-eksisi.

Ukubi

- Izidingo eziphakeme zobuchwepheshe zabasebenzisi kanye nabasebenzi abalungisa umshini.

- Izindleko zokuthengwa kwemishini yomshini ziyabiza.

Izimboni Nge-CNC Machining Metal

● I-ABS: Emhlophe, ephuzi ngokukhanyayo, emnyama, ebomvu.● I-PA: Emhlophe, ephuzi ngokukhanyayo, emnyama, eluhlaza okwesibhakabhaka, eluhlaza.● I-PC: Esobala, emnyama.● PP: Emhlophe, emnyama.● I-POM: Okumhlophe, okumnyama, okuluhlaza okotshani, okumpunga, okuphuzi, okubomvu, okuluhlaza okwesibhakabhaka, okuwolintshi.

Ukuthunyelwa Kucutshungulwa

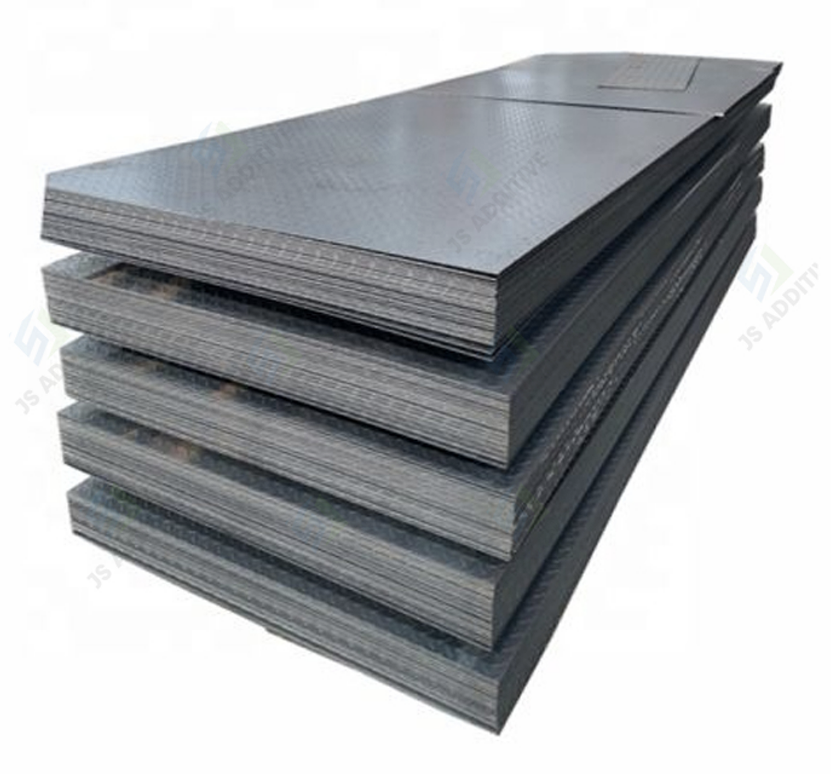

Ngezinto eziningi zensimbi, nazi izindlela zokucubungula okuthunyelwe ezitholakala ku-JS Additive.

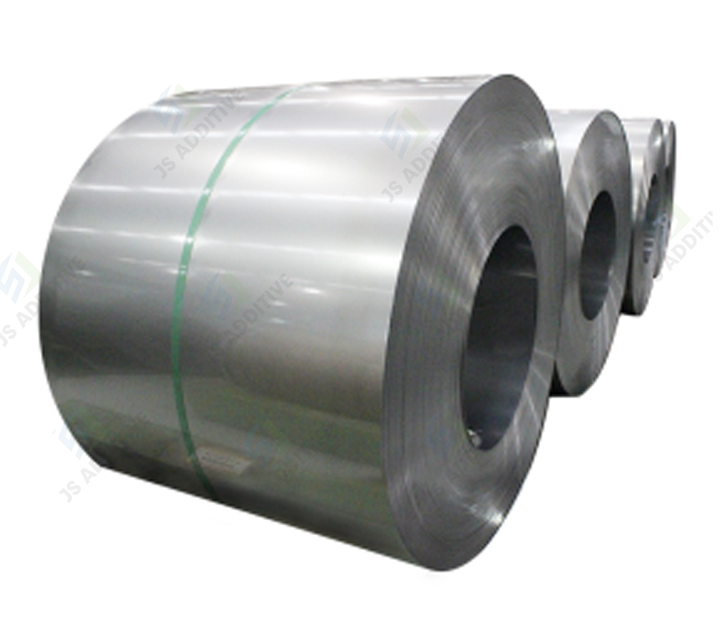

CNC Machining Metal Materials

I-JS Additive Nikeza I-CNC Machining Metal Materials: I-Aluminium Alloy, Ithusi, S45C, Q235 Steel, Sainless Steel, Titanium Alloy, D2 Steel, Magnesium Alloy

Isevisi engcono kakhulu ye-CNC Machining Metal Technique evela ku-JS Additive.