Melemo

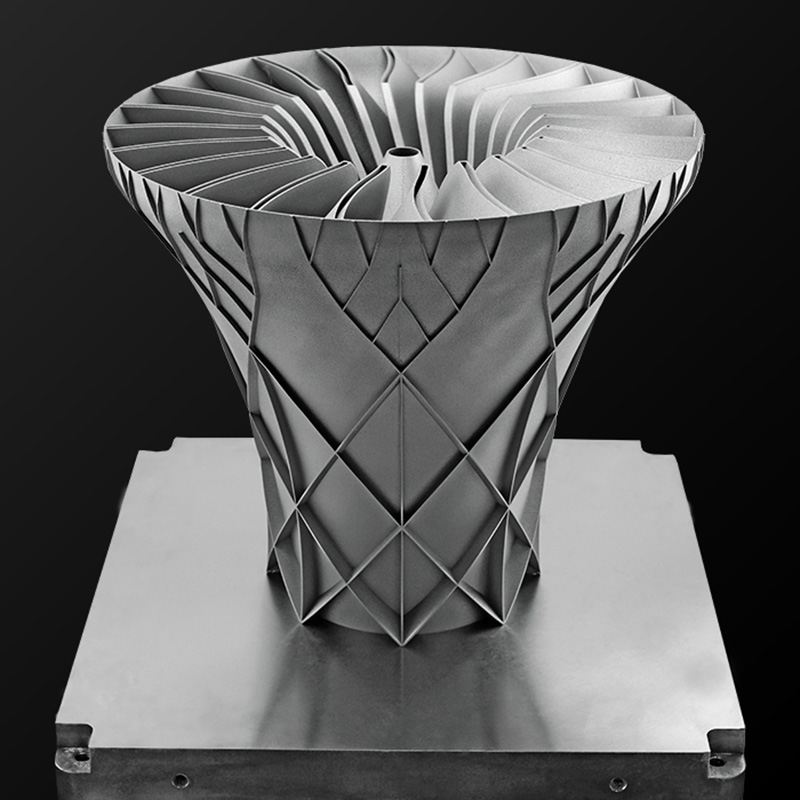

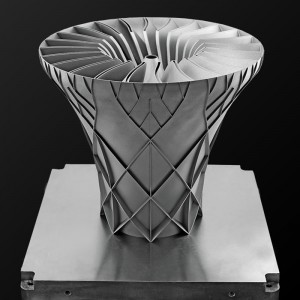

Matla a phahameng a mocheso

E babatsehang khanyetso ea corrosion

Matla a khethehileng a phahameng

Likopo tse Ntle

Sepakapaka

Bongaka

Tsa makoloi

Letlapa la lintlha tsa tekheniki

| Lintho tse akaretsang tsa 'mele (lisebelisoa tsa polymer) / karolo ea boima ba 'mele (g/cm³, thepa ea tšepe) | |

| Boima ba karolo | 4.40 g/cm³ |

| Thermal thepa (lisebelisoa tsa polymer) / thepa ea mmuso e hatisitsoeng (tataiso ea XY, lisebelisoa tsa tšepe) | |

| matla a tšepe | ≥1100 MPa |

| Kotulo Matla | ≥950 MPa |

| Elongation ka mor'a khefu | ≥8% |

| Vickers hardness (HV5/15) | ≥310 |

| Thepa ea mochini (lisebelisoa tsa polymer) / thepa e tšoaroang ke mocheso (tataiso ea XY, lisebelisoa tsa tšepe) | |

| matla a tšepe | ≥960 MPa |

| Kotulo Matla | ≥850 MPa |

| Elongation ka mor'a khefu | ≥10% |

| Vickers hardness (HV5/15) | ≥300 |

-

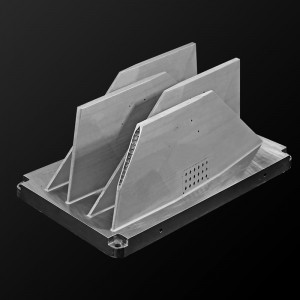

SLA Resin Rubber joalo ka White ABS joalo ka KS198S

-

SLA Resin liquid photopolymer PP joaloka White Som ...

-

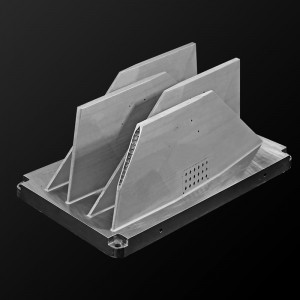

Ts'ebetso e Ntle ea Welding SLM Metal Stainless St...

-

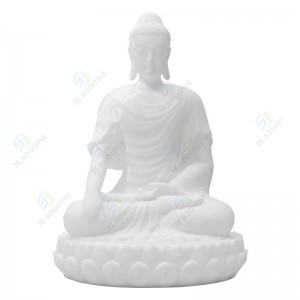

Sebopeho se Botle sa Bokaholimo le Bothata bo Botle ba SLA A...

-

SLA Resin ABS e tšoarellang e tšoarellang joalo ka Somos® GP P...

-

Mocheso o Phahameng oa ho hanyetsa SLA Resin ABS joalo ka ...