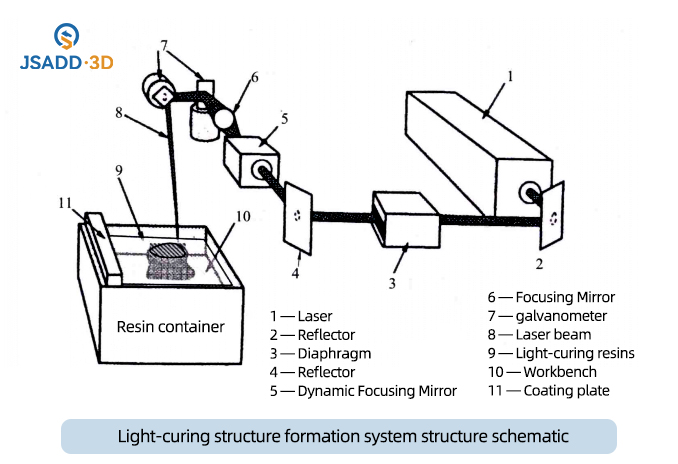

The hardware part of the light curing forming system is mainly composed of laser, optical path system (component 1-6 in Figure), scanning irradiation system (component 7 in Figure) and layering curing forming system (component 9-10 in Figure ).

The light path and scanning irradiation system have various forms, and the light source is mainly ultraviolet light with wavelength of 325 ~ 355 nm. The equipment includes ultraviolet lamp, He-CO laser, subion laser, YAG laser and YV04 laser, etc. The equipment includes ultraviolet lamp, He-CO laser, Subion laser, YAG laser and YV04 laser, etc. Currently, HE -CO laser and YV04 laser are commonly used. There are two types of radical methods: X, Y scanner and spinning mirror scanning. The most commonly used is the galvanometer scanning system

The laser beam is emitted from the laser, and the diameter of the beam is usually 1 to 3 mm. The laser beam is refracted through the reflector and passes through the diaphragm to the reflector, which is then refracted into the dynamic focusing mirror. The laser beam passes through the beam expanding mirror of the dynamic focusing system and then through the convex lens to focus. The focused laser beam is projected onto the first galvanometer, called the X-axis galvanometer, and refracted from the X-axis galvanometer to the Y-axis galvanometer. Finally,the laser beam is projected onto the surface of the liquid light-cured resin.

The computer program controls the x-axis and y-axis galvanometer deflection, so that the laser spots projected on the surface of the resin can be scanned along the X-Y axis plane, and the section shape of the three-dimensional model is scanned to the optical resin to curing it. Then the computer program controls the workbench that supports the forming parts to drop a set height, so that liquid resin can pass through the solid resin. Then the coating plate is controlled to move along the plane so that the cured resin surface is coated with a thin layer of liquid resin. The computer then controls the laser beam to scan the next section and repeat until the model is complete.

The above is to introduce the analysis of JSADD SLA 3D printer light curing forming system. Hope to provide you with a reference.

Having experienced engineers who can offer best solutions for your projects according to your requirements, JSADD 3D is your reliable prototype one-stop solution provider.

Contributor:Sammi