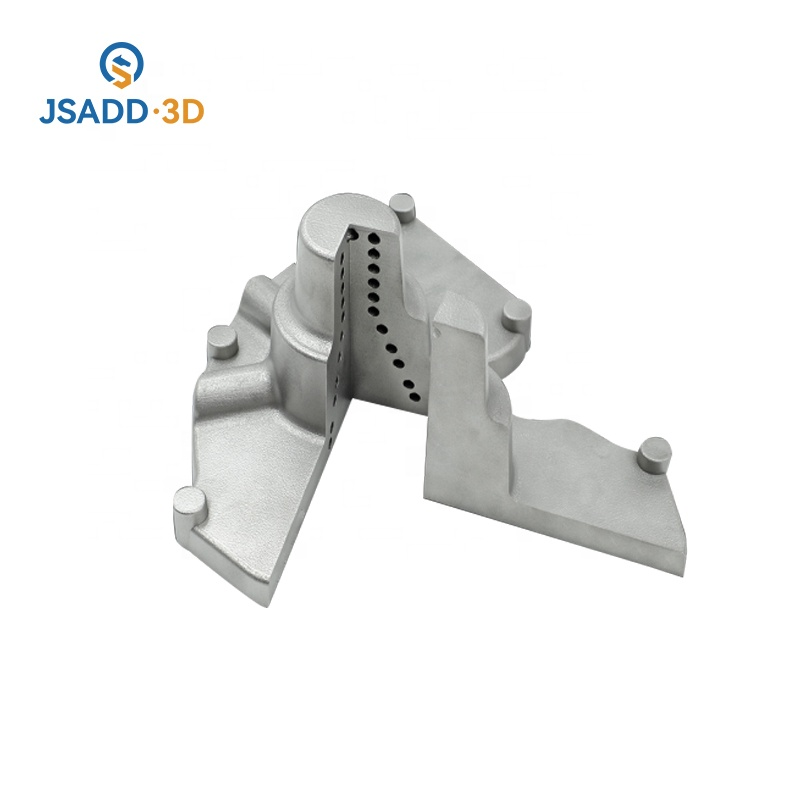

SLM is a technology in which metal powder is completely melted under the heat of a laser beam and then cooled and solidified. The parts in standard metals with high density, which can be further processed as any welding part.

Advantages

Most people think that CNC machining can make basically anything. But the truth is that "basically" sometimes new equipment needs to be built before a part with a high level of complexity can be made. This is the main advantage of metal 3d printing - it allows for almost unlimited production of complex shapes.

Other advantages of using metal 3d printing are:

1.3D printers can create complex details faster than traditional manufacturing methods.

2.Costs are lower than traditional manufacturing methods.

3.Depending on the technology chosen, fine items with extremely minute details can be created.

4.3D printing details can be combined, ultimately saving time and money.

5.More complex compositions mean that parts can be lighter in weight without sacrificing strength. This is why 3D printed parts are in such high demand in the aerospace industry.

6.Metal 3D printing wastes little to no material

Available Material

The main standard metals used at present are the following four materials.

1.Aluminum alloy

2.316L stainless steel

3.Titanium alloys

4.MS1(18Ni300)

Available Post Process

1.Polish

2.Sandblast

3.Electroplate

Ideal Applications

3D printing technology has been widely used in aerospace, automotive, moulds, biomedical, electronics, construction and other fields.

Conclusion

Overall, metal 3D printing not only gives designers more freedom to use their creativity, but also saves a lot of money on product manufacturing, reduces weight and improves product stability. In terms of metal 3D printing in aerospace, the weight of an aircraft can be reduced by installing components such as metal 3D printed seatbelt buckles with honeycomb grooves, further reducing the fuel costs of the aircraft.

If you want to get more informations, Welcome Contact US.

Related Video:

Author: Karianne | Lili Lu | Seazon