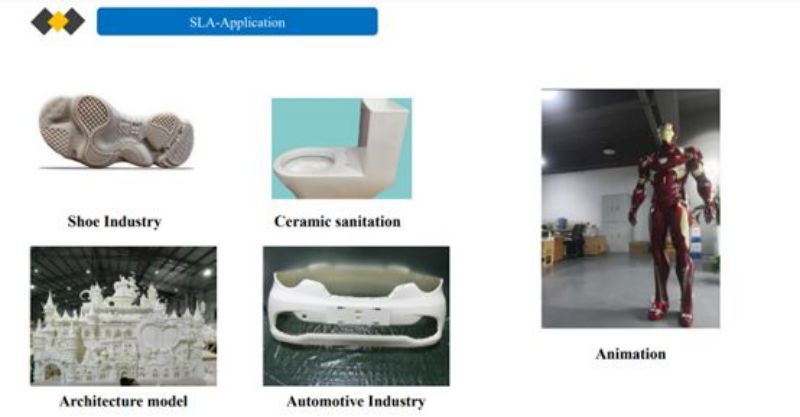

Stereolithography (SLA) is an industrial 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries in as fast as 1 day. SLA, or stereolithography, is a widely-used 3D printing process and the most popular of the resin printing technologies. The process owes its esteem in the additive space to its ability to produce prototypes that are accurate, isotropic and watertight, as well as production parts with impressive surface smoothness and more detailed features. Despite its host of advantages, though, it's tricky to know whether SLA will yield the best results for your specific parts. In this introduction to SLA, we cover the basic principles of the process to determine whether it's suitable for your application. Stereolithography (SLA) is an additive manufacturing process that belongs to the vat photopolymerization family.

How does SLA 3D printing work ?

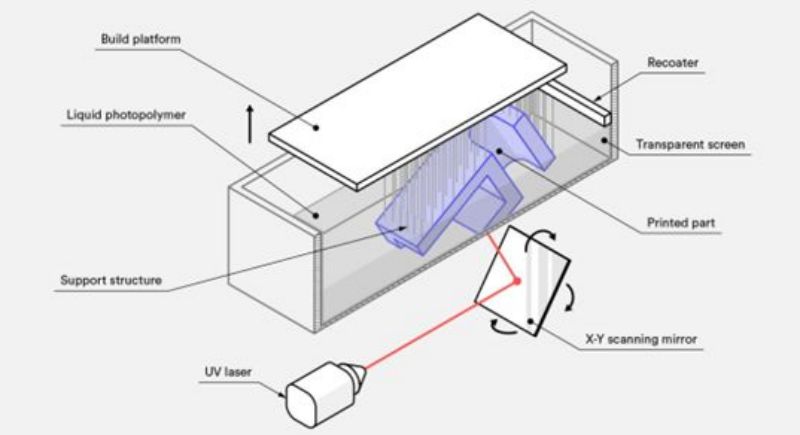

1.SLA 3D printing works by first positioning the build platform in the tank of liquid photopolymer, at a distance of one layer height for the surface of the liquid.

2.A UV laser creates the next layer by selectively curing and solidifying the photopolymer resin.

3.During the solidification part of the photopolymerization process, the monomer carbon chains that compose the liquid resin are activated by the light of the UV laser and become solid, creating strong unbreakable bonds between each other.

4.The laser beam is focused in a predetermined path using a set of mirrors, called galvos. Thewhole cross-sectional area of the model is scanned, so the produced part is fully solid.

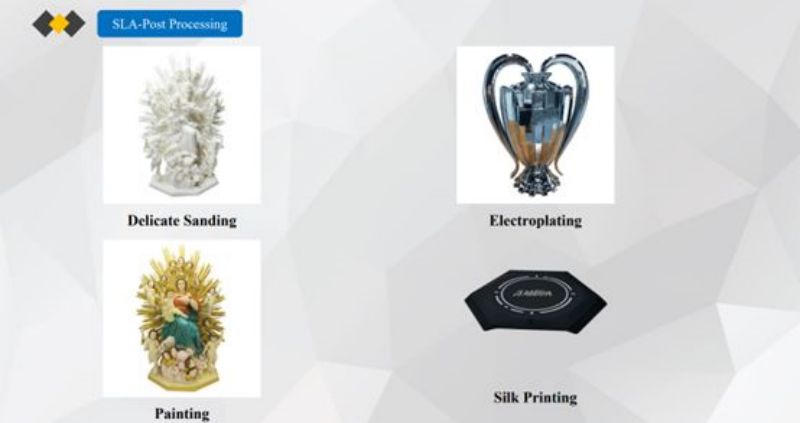

5.After printing, the part is in a not-fully-cured state. It requires further post-processing under UV light if very high mechanical and thermal properties are required.

The photopolymerization process is irreversible and there is no way to convert the SLA parts back to their liquid form. Heating these SLA parts will cause them to burn instead of melt. This is because the materials that are produced with SLA are made of thermoset polymers, as opposed to the thermoplastics that fused deposition modeling (FDM) uses.

JSADD 3D SLA 3D Printing

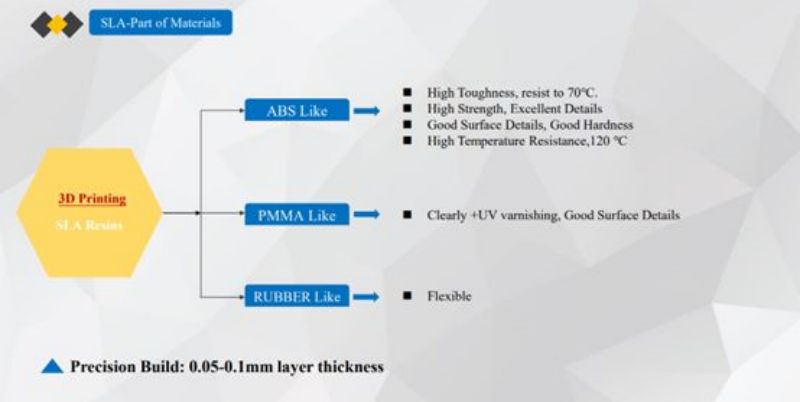

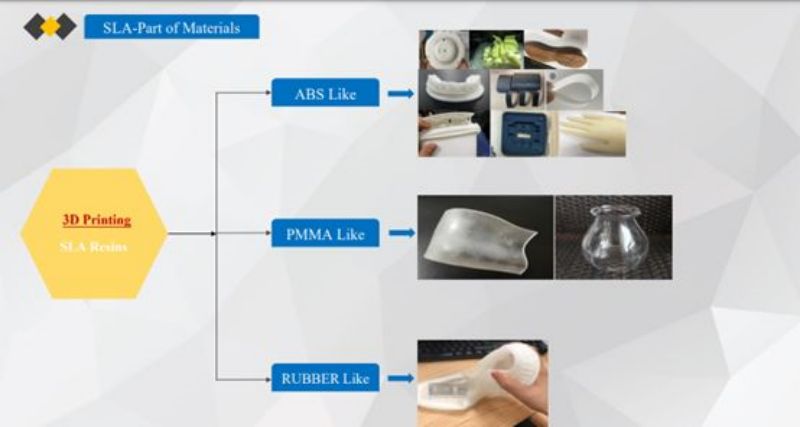

SLA printers: 100+sets--ABS,PP,PMMA,Rubber material(biggest size:1700*800*600mm)

Welcome contact JSADD 3D Print Manufacturer.

Author: Jessica / Lili Lu / Seazon