On July 13, 2023, Prof. Gang Wang's team at the Institute of Materials Research of Shanghai University published their latest research results "Microstructural evolution and mechanical properties of (FeCoNi)85.84Al7.07Ti7.09 high-entropy alloy by selective laser melting with aging treatment", which utilizes the highly efficient additive manufacturing process and short-term aging process to produce ((FeCoNi)85.84Al7.07Ti7.09) high-entropy alloy. FeCoNi)85.84Al7.07Ti7.09 high-entropy alloy, which exhibits excellent mechanical properties, with an ultimate tensile strength of 1625 MPa, a yield strength of 1214 MPa, and an elongation at break of 11.6%. Professor Jia Yandong and Dr. Mu Yongkun are the co-corresponding authors.

Key findings

This work investigated the effect of aging treatment on the microstructural evolution and mechanical properties of (FeCoNi)85.84Al7.07Ti7.09HEA produced by SLM . The following conclusions were drawn.

(1) Two strengthening mechanisms, dislocation strengthening and precipitation strengthening, were introduced in FCNAT HEA using SLM technique and short-term aging treatment at 780°C. As a result, a combination of high-density dislocations and precipitated phases can be achieved in FCNAT 780, resulting in optimal mechanical properties (yield strength σ0.2, ultimate tensile strength σUTS, and elongation at break εf values of 1214 MPa, 1625 MPa, and 11.6%, respectively).

(2) The phase compositions of the SLM samples and aged samples were mainly composed of the FCC phase, L12 and L21 phases. After aging treatment, L12 and L21 phases precipitated and the content of L12 and L21 phases gradually decreased with the increase of aging treatment temperature.

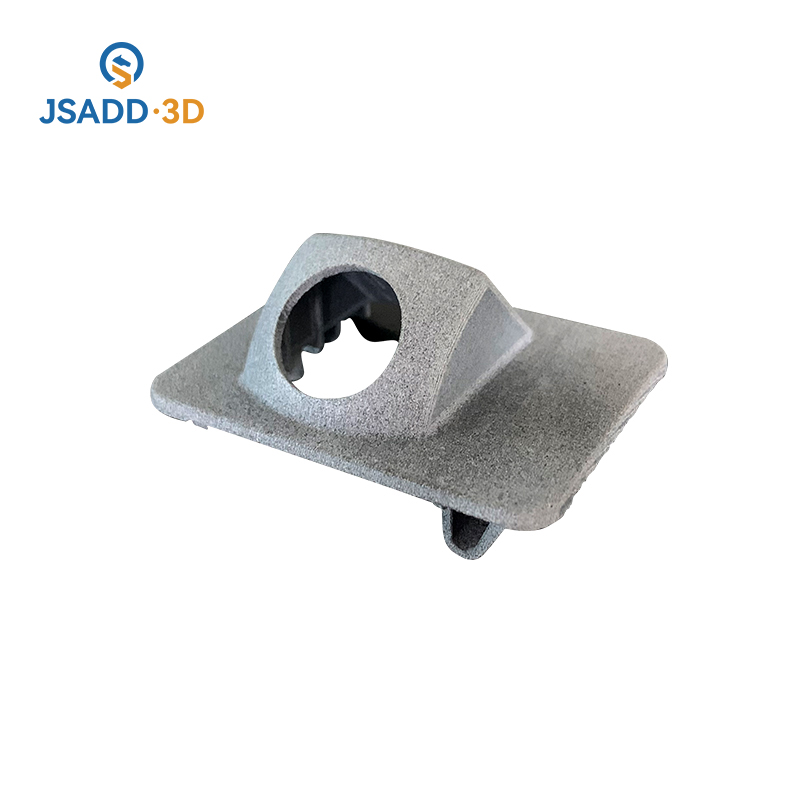

If you want to know more information and need to make 3d printing model, please contact JSADD 3D Manufacturer every time.

Author: Yolanda/Lili Lu/Seazon