Ukuncibilika kwe-Electron Beam(EBM)

I-Electron Beam Selective Melting (EBSM) Isimiso

Okufana ne-laser selective sintering kanyeUkuncibilika kwe-Laser okukhethiweizinqubo, ubuchwepheshe be-electron beam selective melting technology (EBSM) ubuchwepheshe bokukhiqiza obusheshayo obusebenzisa imishayo ye-electron yamandla aphezulu kanye nesivinini esikhulu ukukhetha impushana yensimbi eyibhomu, ngaleyo ndlela incibilike futhi yakhe izinto eziyimpushana.

Inqubo ye-EBSM ubuchwepheshe bumi kanje: okokuqala, sakaza ungqimba lwempushana endizeni yokusabalalisa impushana; khona-ke, ngaphansi kokulawulwa kwekhompiyutha, i-electron beam iyancibilika ngokukhetha ngokusho kolwazi lwephrofayili ye-cross-sectional, futhi i-powder yensimbi iyancibilika ndawonye, ihlanganiswe nengxenye eyenziwe ngezansi, futhi inqwabelanise ungqimba ngongqimba kuze kube yilapho yonke ingxenye isincibilike ngokuphelele; Ekugcineni, impushana eyeqile iyasuswa ukuze kukhiqizwe umkhiqizo owunxantathu ofunekayo. Isignali yokuskena yesikhathi sangempela sekhompuyutha ephezulu idluliselwa ejokeni lokuchezuka ngemva kokuguqulwa kwedijithali-kuya-analogi kanye nokukhulisa amandla, futhi i-electron beam ichezukiswa ngaphansi kwesenzo senkundla kazibuthe ekhiqizwe i-voltage yokuchezuka ehambisanayo ukuze kuzuzwe ukuncibilika okukhethiwe. Ngemva kweminyaka engaphezu kweshumi yocwaningo, kutholakala ukuthi ezinye izinqubo nemingcele ezifana electron ugongolo zamanje, egxile zamanje, isikhathi isenzo, powder ukushuba, ngesivinini voltage, kanye nemodi ukuskena kwenziwa ucwaningo orthogonal. Isikhathi sesenzo sinomthelela omkhulu ekwakhiweni.

Izinzuzoye-EBSM

Ubuchwepheshe bokwakha insimbi eqondile ye-electron beam busebenzisa imishayo ye-electron enamandla amakhulu njengomthombo wokushisa wokucubungula. Ukwakheka kokuskena kungenziwa ngaphandle kwe-inertia yomshini ngokulawula ikhoyili ephambukayo kazibuthe, futhi indawo yokugezela ye-electron beam ingavimbela futhi impushana yensimbi ukuthi ifakwe i-oxid ngesikhathi sesigaba soketshezi sintering noma ukuncibilika. Uma kuqhathaniswa ne-laser, i-electron beam inezinzuzo zezinga eliphezulu lokusebenzisa amandla, ukujula okukhulu kwesenzo, izinga eliphezulu lokumuncwa kwezinto ezibonakalayo, ukuzinza kanye nezindleko eziphansi zokusebenza nezokulungisa. Izinzuzo zobuchwepheshe be-EBM zifaka ukusebenza kahle okuphezulu kokwenza, ukuguqulwa kwengxenye ephansi, asikho isidingo sokusekelwa kwensimbi phakathi nenqubo yokubunjwa, i-denser microstructure, njalonjalo. Ukuchezuka kwe-electron beam kanye nokulawula kokugxila kuyashesha futhi kuyazwela. Ukuchezuka kwelaser kwenza kudingeke ukuthi kusetshenziswe isibuko esidlidlizayo, futhi isivinini esizungezayo sesibuko esidlidlizayo sishesha kakhulu uma i-laser iskena ngesivinini esikhulu. Lapho amandla e-laser ekhuphuka, i-galvanometer idinga uhlelo lokupholisa oluyinkimbinkimbi, futhi isisindo sayo sanda kakhulu. Njengomphumela, uma usebenzisa ukuskena kwamandla aphezulu, isivinini sokuskena se-laser sizokhawulelwa. Lapho uskena ububanzi obukhulu bokubunjwa, ukuguqula ubude obugxilile be-laser nakho kunzima. Ukuchezuka nokugxila kwe-electron beam kwenziwa ngozibuthe. Ukuchezuka kanye nobude obugxilile be-electron beam bungalawulwa ngokushesha nangokuzwela ngokushintsha ukuqina nokuqondisa kwesignali kagesi. I-electron beam deflection focusing system ngeke iphazanyiswe ukuhwamuka kwensimbi. Lapho kuncibilika insimbi ngamalaser nemishayo yama-electron, umhwamuko wensimbi uzosakazeka kuso sonke isikhala sokwakheka futhi umboze ubuso banoma iyiphi into ethinta ifilimu yensimbi. Ukuchezuka nokugxila kwemishayo ye-electron konke kwenziwa endaweni kazibuthe, ngakho-ke ngeke kuthinteke ukuhwamuka kwensimbi; amadivaysi okukhanya afana nama-laser galvanometers angcoliswa kalula ukuhwamuka.

Laser Minatal Idiphozithi(LMD)

I-Laser Metal Deposition (LMD) yahlongozwa okokuqala yiSandia National Laboratory e-United States ngeminyaka yawo-1990, yase ithuthukiswa ngokulandelana ezingxenyeni eziningi zomhlaba. Njengoba amanyuvesi amaningi nezikhungo zenza ucwaningo ngokuzimela, lobu buchwepheshe Kunamagama amaningi, nakuba amagama awafani, kodwa izimiso zawo ziyafana. Phakathi nenqubo yokubumba, impushana iqoqwa endizeni esebenzayo ngokusebenzisa umlomo wombhobho, futhi ugongolo lwe-laser nalo luqoqwa kuleli phuzu, futhi amaphuzu okwenziwa okuyimpushana kanye nokukhanya ayenzeka ngengozi, futhi into enqwabelene enqwabelene itholakala ngokuhamba ngetafula lokusebenza noma umlomo.

Ubuchwepheshe be-LENS isebenzisa ama-laser ekilasi-kilowatt. Ngenxa yendawo enkulu okugxilwe kuyo nge-laser, ngokuvamile engaphezu kuka-1mm, nakuba izinto zensimbi ezicinene eziboshwe ngensimbi zingatholakala, ukunemba kwazo kobukhulu kanye nokuqedwa kwendawo akukuhle kakhulu, futhi umshini oqhubekayo uyadingeka ngaphambi kokusetshenziswa. I-Laser cladding iyinqubo ye-metallurgical eyinkimbinkimbi ngokomzimba namakhemikhali, futhi imingcele yenqubo yokuhlanganisa inethonya elikhulu kwikhwalithi yezingxenye ezigqoke. Imingcele yenqubo ekuhlanganisweni kwe-laser ikakhulukazi ihlanganisa amandla e-laser, ububanzi bendawo, inani lokungagxili, ijubane lokuphakela impushana, isivinini sokuskena, izinga lokushisa lechibi elincibilikisiwe, njll., okunomthelela omkhulu esilinganisweni sokuhlanjululwa, ukuqhekeka, ukuhwalala komhlaba kanye nokubumbana kwezingxenye zokuvala. Ngesikhathi esifanayo, ipharamitha ngayinye nayo ithinta omunye nomunye, okuyinto inqubo eyinkimbinkimbi kakhulu. Izindlela zokulawula ezifanele kufanele zamukelwe ukuze kulawulwe izici ezihlukahlukene ezithonyayo ngaphakathi kohlu oluvumelekile lwenqubo yokuhlanganisa.

NgqoI-Metal Laser Sphakathiing(DMLS)

Ngokuvamile kunezindlela ezimbili zokuthiI-SLSukwenza izingxenye zensimbi, enye iyindlela engaqondile, okungukuthi, i-SLS ye-polymer-coated metal powder; enye indlela eqondile, okungukuthi, I-Direct Metal Laser Sintering (DMLS) .Njengoba ucwaningo lwe-laser sintering eqondile yempushana yensimbi lwenziwa eNyuvesi yase-Chatofci eLeuvne ngo-1991, ukucwiliswa okuqondile kwempushana yensimbi ukuze kwakhiwe izingxenye ezintathu-ntathu ngenqubo ye-SLS ingenye yemigomo yokugcina ye-prototyping esheshayo. Uma kuqhathaniswa nobuchwepheshe be-SLS obungaqondile, inzuzo enkulu yenqubo ye-DMLS ukuqedwa kwezinyathelo zokwelashwa ezibizayo nezidla isikhathi kanye nezinqubo zangemuva kokwelashwa.

Izici kwe-DMLS

Njengegatsha lobuchwepheshe be-SLS, ubuchwepheshe be-DMLS ngokuyisisekelo bunomgomo ofanayo. Kodwa-ke, kunzima ukwenza ngokunembile izingxenye zensimbi ezinezimo eziyinkimbinkimbi ngobuchwepheshe be-DMLS. Ekuhlaziyweni kokugcina, ikakhulukazi ngenxa yomphumela "we-spheroidization" kanye ne-sintering deformation ye-metal powder ku-DMLS. I-Spheroidization yinto lapho umumo ongaphezulu woketshezi lwensimbi encibilikisiwe uguqukela endaweni eyindilinga ngaphansi kokungezwani kobuso phakathi kwensimbi ewuketshezi kanye nendawo ezungezile ukuze kwenziwe uhlelo olwakhiwe ubuso boketshezi lwensimbi encibilikisiwe kanye nengaphezulu lendawo ezungezile ibe namandla amancane amahhala. I-Spheroidization izokwenza impushana yensimbi ingakwazi ukuqina ngemva kokuncibilika ukuze yakhe ichibi elincibilikisiwe eliqhubekayo nelibushelelezi, ngakho izingxenye ezibunjiwe zikhululekile futhi zinezimbotshana, okuholela ekuhlulekeni kokubumba. Ngenxa ye-viscosity ephezulu kakhulu ye-powder yensimbi yengxenye eyodwa esigabeni sokucwilisa uketshezi, umphumela we-"spheroidization" ubucayi kakhulu, futhi ububanzi obuyindilinga buvame ukuba bukhulu kunobubanzi bezinhlayiya zempushana, okuholela enanini elikhulu lezimbotshana ezingxenyeni ezisindisiwe. Ngakho-ke, i-DMLS ye-single-component metal powder ineziphambeko ezisobala zenqubo, futhi ngokuvamile idinga ukwelashwa okulandelayo, hhayi umqondo wangempela "we-sintering ngqo".

Ukuze unqobe umkhuba we-"spheroidization" wengxenye eyodwa ye-metal powder DMLS kanye nomphumela wokukhubazeka kwenqubo efana ne-sintering deformation kanye nokuminyana okuxekethile, ngokuvamile ingafinyelelwa ngokusebenzisa izimpushana zensimbi ezinezingxenye eziningi ezinamaphoyinti ahlukene okuncibilika noma ukusebenzisa izimpushana zangaphambili. Uhlelo lwempushana yensimbi enezingxenye eziningi ngokuvamile lwakhiwe ngezinsimbi ezincibilika kakhulu, izinsimbi ezincibilika eziphansi nezinye izinto ezengeziwe. Indawo ephezulu yokuncibilika yensimbi eyimpushana njengoba insimbi yohlaka lwamathambo ingagcina umongo wayo oqinile ku-DMLS. I-low-melting point metal powder isetshenziswa njengensimbi ehlanganisayo, encibilikiswa ku-DMLS ukuze yakhe isigaba se-liquid, futhi amajazi esigaba soketshezi aphumayo, amanzise futhi abophe izinhlayiya zensimbi zesigaba esiqinile ukuze kuzuzwe ukuminyana kwe-sintering.

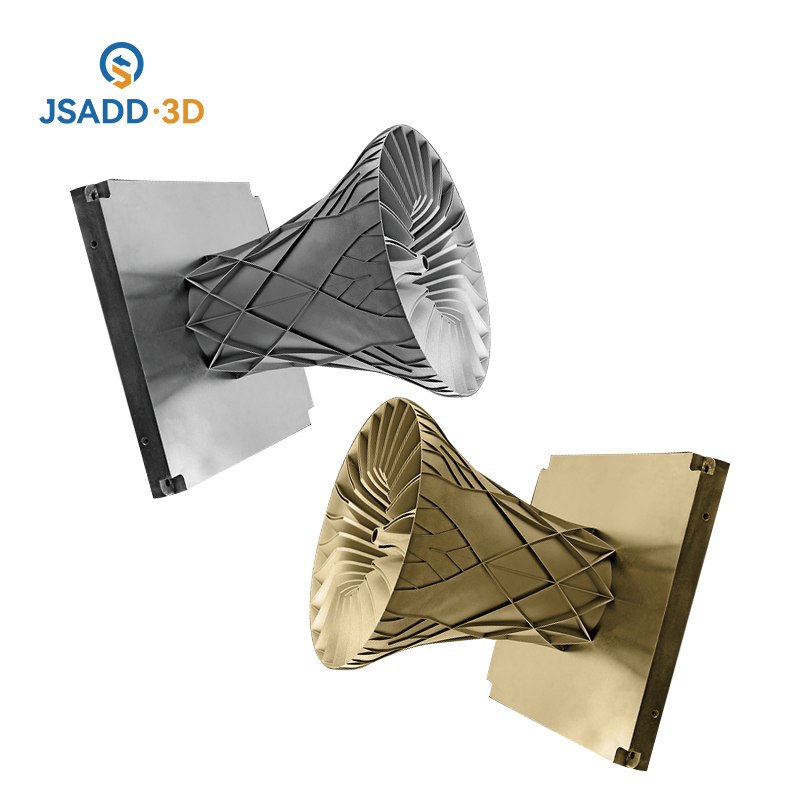

Njengenkampani ehamba phambili eChinaIsevisi yokuphrinta ye-3Dimboni,I-JSADD3D ngeke ikhohlwe inhloso yayo yasekuqaleni, yandise ukutshalwa kwezimali, isungule futhi ithuthukise ubuchwepheshe obengeziwe, futhi ikholelwa ukuthi izoletha ulwazi olusha lokuphrinta lwe-3D emphakathini.

Umnikeli: Sammi