-

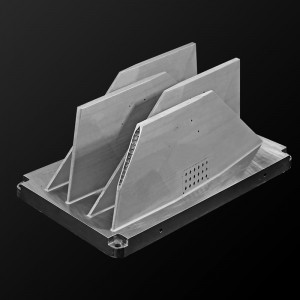

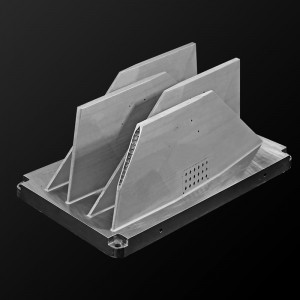

SLA Resin Rubber joalo ka White ABS joalo ka KS198S

Kakaretso ea Boitsebiso

KS198S ke resin e tšoeu, e tenyetsehang ea SLA e nang le likarolo tse thata haholo, elasticity e phahameng le ho thetsoa ha bonolo.E loketse ho hatisa mohlala oa lieta, sekoaelo sa rabara, mofuta oa biomedical le likarolo tse ling tse kang rabara. -

Phahameng Mocheso Ressitance SLA Resin ABS joaloka KS1208H

Kakaretso ea BoitsebisoKS1208H ke resin ea SLA e hanyetsanang le nako e phahameng e nang le viscosity e tlase ka 'mala o khanyang.Karolo e ka sebelisoa ka mocheso o ka bang 120 ℃.Bakeng sa mocheso oa hang-hang o mamella ho feta 200 ℃.E na le botsitso bo botle ba sebopeho le lintlha tse ntle tsa bokaholimo, e leng tharollo ea sefahleho bakeng sa likarolo tse hlokang ho hanyetsa mocheso le mongobo, hape e sebetsa bakeng sa hlobo e potlakileng e nang le thepa e itseng tlhahisong e nyane ea batch.

-

Ts'ebetso e Ntle ea Welding SLM Metal Stainless Steel 316L

316L tšepe e sa hloekang ke thepa e ntle ea tšepe bakeng sa likarolo tse sebetsang le likarolo tse ling.Likarolo tse hatisitsoeng li bonolo ho li hlokomela kaha li hohela litšila tse nyane mme ho ba teng ha chrome ho e fa molemo o eketsehileng oa ho se be le mafome.

Mebala e Fumanehang

Hlooho

E fumaneha Post Process

Sepolishe

Sandblast

Electroplate

-

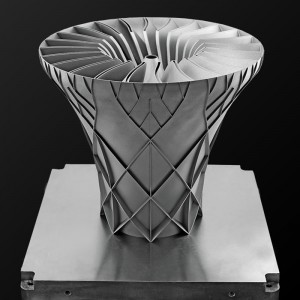

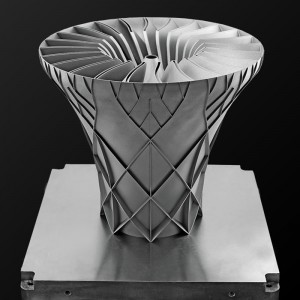

Tlas'a Density Empa Matla a Phahameng a Phahameng SLM Aluminium Alloy AlSi10Mg

SLM ke thekenoloji eo ho eona phofo ea tšepe e qhibilihisitsoeng ka ho feletseng tlas'a mocheso oa sefate sa laser ebe e pholile ebe e tiisa.Lisebelisoa tse ka sehloohong tse sebelisoang hona joale ke lisebelisoa tse 'nè tse latelang.

Aluminium alloy ke sehlopha se sebelisoang ka ho fetesisa sa lisebelisoa tsa sebopeho sa tšepe tse se nang ferrous indastering.Mehlala e hatisitsoeng e na le boima bo tlase empa matla a batlang a le holimo a haufi kapa a feta tšepe ea boleng bo holimo le polasetiki e ntle.

Mebala e Fumanehang

Hlooho

E fumaneha Post Process

Sepolishe

Sandblast

Electroplate

Anodize

-

Matla a Khethehileng a Phahameng a SLM Titanium Alloy Ti6Al4V

Li-alloys tsa Titanium ke li-alloys tse thehiloeng ho titanium le likarolo tse ling tse kentsoeng.Ka litšobotsi tsa matla a phahameng, khanyetso e ntle ea kutu le ho hanyetsa mocheso o phahameng, e 'nile ea sebelisoa haholo libakeng tse sa tšoaneng.

Mebala e Fumanehang

Bosoeu ba silevera

E fumaneha Post Process

Sepolishe

Sandblast

Electroplate

-

Matla a Phahameng & Matla a Matla a SLS Nylon White/Grey/Black PA12

Khetho ea laser sintering e ka etsa likarolo ka polasetiki e tloaelehileng e nang le thepa e ntle ea mochini.

PA12 ke thepa e nang le thepa e phahameng ea mochini, 'me sekhahla sa tšebeliso se haufi le 100%.Ha ho bapisoa le lisebelisoa tse ling, phofo ea PA12 e na le litšobotsi tse babatsehang tse kang metsi a mangata, motlakase o tlaase o tsitsitseng, ho monya metsi a tlaase, ho qhibiliha ho itekanetseng le ho nepahala ha lihlahisoa tse phahameng.Ho hanyetsa mokhathala le ho tiea ho ka boela ha kopana le li-workpieces tse hlokang thepa e phahameng ea mochine.

Mebala e Fumanehang

Bosweu/Botsho/Botsho

E fumaneha Post Process

Ho daea

-

E Loketseng Bakeng sa Likarolo Tse Matla tse Ts'ebetsong tse rarahaneng MJF Black HP PA12

HP PA12 ke thepa e nang le matla a phahameng le ho hanyetsa mocheso o motle.Ke polasetiki e felletseng ea boenjiniere ba thermoplastic, e ka sebelisoang bakeng sa netefatso ea pele ho mohlala mme e ka tlisoa e le sehlahisoa sa ho qetela.

-

E loketse Likarolo tse thata le tse sebetsang MJF Black HP PA12GB

HP PA 12 GB ke sefaha sa khalase se tletseng phofo ea polyamide e ka sebelisoang ho hatisa likarolo tse thata tse sebetsang tse nang le thepa e ntle ea mochine le ho sebelisoa hape ho phahameng.

Mebala e Fumanehang

Hlooho

E fumaneha Post Process

Ho daea

-

Mokhoa o bonolo oa ho etsa Vacuum Casting ABS joalo ka PX1000

E sebelisoa ka ho kenya liforomo tsa silicone bakeng sa ho phethahatsa likarolo tsa prototype le li-mock-ups tseo thepa ea tsona e leng haufi le ea thermoplastics.

E ka penta

Karolo ea Thermoplastic

Nako e telele ea pitsa

Lintho tse ntle tsa mochini

Viscosity e tlase

-

Matla a Phahameng a Mechanical Leseli Weight Vacuum Casting PP joalo ka

Ho hlahisa likarolo tsa prototype le li-mock-ups tse nang le thepa ea mochini joalo ka PP le HDPE, joalo ka phanele ea lisebelisoa, bumper, lebokose la lisebelisoa, sekoaelo le lisebelisoa tse thibelang ho thothomela.

• 3-likarolo tsa polyurethane bakeng sa vacuum casting

• bolelele bo phahameng

• Ho sebetsa habonolo

• Flexural modulus e fetolehang

• Ho hanyetsa tšusumetso e phahameng, ha ho na ho robeha

• Ho tenyetseha hantle

-

Mehato e Ntle ea ho Itšetsa ka Self-lubricability Vacuum Casting POM

E tla sebelisoa ke vacuum casting ka har'a hlobo ea silicone bakeng sa ho etsa likarolo tsa prototype le li-mock-ups tse nang le thepa ea mochini e ts'oanang le thermoplastics joalo ka polyoxymethylene le polyamide.

• High flexural modulus ea elasticity

• Ho nepahala ho phahameng ho hlahisa

• E fumaneha ka makhetlo a mabeli (4 le 8 mets.)

• E ka mebala habonolo ka li-pigments tsa CP

• Ho senya ka potlako

-

Khahlano e Ntle ea Tšusumetso ea CNC Machining ABS

Letlapa la ABS le na le matla a ho hanyetsa mocheso, ho hanyetsa mocheso, ho hanyetsa mocheso o tlaase, lik'hemik'hale tsa lik'hemik'hale le thepa ea motlakase.Ke sesebelisoa sa thermoplastic se feto-fetohang bakeng sa ts'ebetso ea bobeli joalo ka ho fafatsa ka tšepe, electroplating, welding, ho tobetsa ho chesang le ho kopanya.Mocheso oa ho sebetsa ke -20 ° C-100 °.

Mebala e Fumanehang

E tšoeu, e mosehla o khanyang, e ntšo, e khubelu.

E fumaneha Post Process

Ho penta

Ho roala

Khatiso ea Silika