Adeegga Daabacaadda Xirfadlayaasha 3D

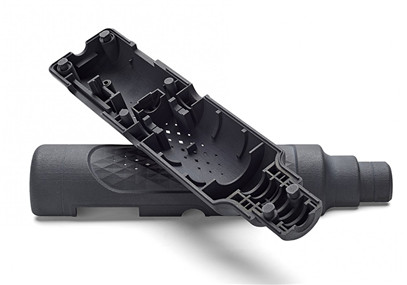

Soo Bandhigida SLM 3D

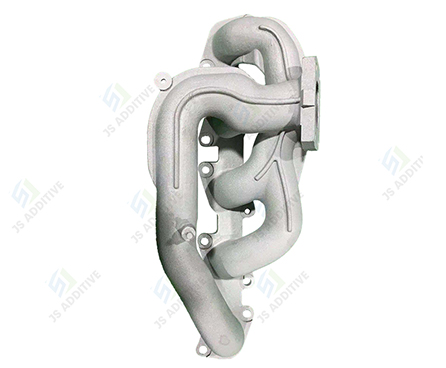

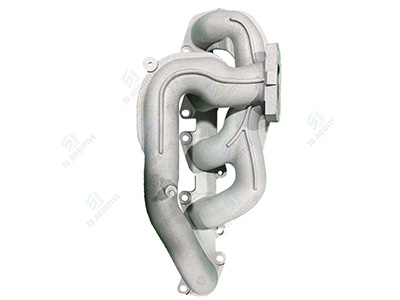

SLM waa tignoolajiyad aad u xiiso badan oo leh codsiyo badan oo suurtagal ah. Marka kiisaska isticmaalku koraan, tignoolajiyadu way koraan, iyo hababka iyo alaabadu noqdaan kuwo raqiis ah, waa inaan aragnaa inay noqoto mid caan ah, si ballaaran ayaa loo isticmaalaa meelo badan.

1- Samee lakabka xiga ee lakabka budada ah ee aan qaabaysan, ka hortag sawirka laysarka ee lakabka budada birta ah ee aadka u weyn iyo burburka;

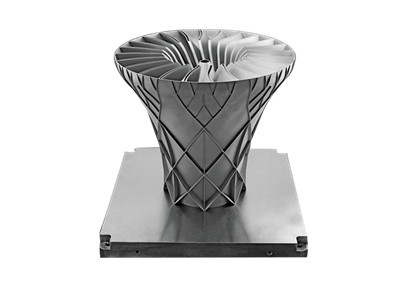

2- Ka dib marka budada la kululeeyo, dhalaalto lana qaboojiyo inta lagu guda jiro habka wax-soo-saarka, waxaa gudaha ku jira diiqad hoos u dhac ah, taas oo keeni karta in qaybaha ay soo baxaan, iwm. Qaab dhismeedka taageerada wuxuu isku xiraa qaybta la sameeyay iyo qaybta aan la samayn, taas oo si wax ku ool ah u xakameyn karta hoos u dhigista iyo ilaalinta dheelitirka cadaadiska qaybta la sameeyay. Ka dib marka la dhammeeyo, taageerada qaabka ayaa laga saari doonaa, oo dusha sare waa dhulka oo lagu nadiifiyaa ciid. Kadibna qaabka waa la dhammeeyaa.

Waa kan sida ay u shaqeyso

Iyada oo la xakameynayo kombuyuutarka, laser-ka ayaa lagu shubi doonaa meesha loogu talagalay, budada birta ah waa la dhalaali doonaa, birta dhalaalaysa waxay si degdeg ah u qaboojin doontaa oo adkeynaysaa. Marka la dhammeeyo hal lakab, substrate-ka samaynta ayaa hoos u dhigi doona dhumucda lakabka, ka dibna lakab cusub oo budo ah ayaa lagu dabaqayaa xoqidda. Habka kor ku xusan waa la soo celin doonaa ilaa workpiece la sameeyay.

Faa'iidooyinka

- Cufnaanta biraha caadiga ah ee lagu farsameeyo habka SLM ayaa ka badan 99%, iyo sifooyinka farsamada ee ugu fiican waxay la mid yihiin hababka dhaqanka

- Si toos ah u naqshadee oo u soo saar qaybo bir ah oo shaqeynaya oo leh qaabab joomatari oo adag iyada oo aan la helin habab dhexdhexaad ah

- Noocyada alaabta la isticmaalayo ayaa sii kordhaya, qaybaha la warshadeeyayna waa la alxan karaa mar dambe

- Hagaajinta naqshadaynta alaabta, ku beddel jidhka adag ee asalka ah qaab dhismeed adag oo macquul ah si miisaanka alaabta la dhammeeyey uu hooseeyo, taas oo hoos u dhigaysa qiimaha guud.

Khasaaro

- Xawaaraha daabacaadda oo gaabis ah iyo wakhtiga wax soo saarka oo dheer.

- Dusha moodeel qallafsan, waxay u baahan tahay habayn ka dib si ay u noqoto mid qurux badan.

- Dusha qaabka qallafsan iyo saxnaanta xad yar.

Warshadaha leh daabacaadda SLM 3D

Qaybaha Dhismaha / Qaybaha Gawaadhida / Qaybaha Duulista (Diyaaradaha) / Soo saarista Mashiinada / Caafimaadka Mashiinada / Waxsoosaarka Caaryada / Qaybaha

Processing ka dib

Habka SLM waxa uu inta badan u qaybsan yahay daawaynta kulaylka, biraha jarista siligga, dacaayadeynta, shiididda, ciid-qarxinta iyo wixii la mid ah.

Qalabka SLM

Dhaleeceynta Laser Selective (SLM) iyo Direct Metal Laser Sintering (DMLS) waa laba hab oo wax soo saar bir ah oo lagu daro oo ka tirsan qoyska daabacaadda 3D ee isku-dhafka sariirta. Qalabka loo isticmaalo geeddi-socodka waa dhammaan biraha granular.

| SLM | Qaabka | Nooca | Midabka | Farsamada | Dhumucda lakabka | Astaamaha |

| Birta aan Caadiga ahayn | 316L | / | SLM | 0.03-0.04mm | Iska caabin daxalka heer sare ah Waxqabadka alxanka wanaagsan |

| Caaryada Birta | 18Ni300 | / | SLM | 0.03-0.04mm | Guryaha farsamada ee wanaagsan Iska caabin aad u fiican |

| Aluminium Aloy | AlSi10Mg | / | SLM | 0.03-0.04mm | Cufnaanta hoose laakiin xoogaa aad u sarreeya Iska caabin daxalka heer sare ah |

| Alloy Titanium | Ti6Al4V | / | SLM | 0.03-0.04mm | Iska caabin daxalka heer sare ah Xoog gaar ah oo sarreeya |

-

Whatsapp

-

Taleefanka

-

E-mailka

-

WeChat

WeChat

-

Sare