Electron Beam Kusungunuka(EBM)

Electron Beam Selective Melting (EBSM) Mfundo yofunika

Zofanana ndi laser selective sintering ndiKusankha Laser KusungunukaNjira, ukadaulo wa electron beam selective melting technology (EBSM) ndiukadaulo wopanga mwachangu womwe umagwiritsa ntchito ma elekitironi amphamvu kwambiri komanso othamanga kwambiri posankha bombard chitsulo ufa, potero amasungunuka ndikupanga zida za ufa.

Ndondomeko ya EBSM luso ndi motere: choyamba, kufalitsa wosanjikiza ufa pa ufa kufalitsa ndege; ndiye, pansi pa ulamuliro wa makompyuta, mtengo wa elekitironi umasungunuka mosankha malinga ndi chidziwitso cha mawonekedwe a mtanda, ndipo ufa wachitsulo umasungunuka pamodzi, kugwirizanitsa ndi gawo lomwe lili pansipa, ndikuwunjika wosanjikiza ndi wosanjikiza mpaka gawo lonse lisungunuka; Pomaliza, ufa wowonjezera umachotsedwa kuti upereke chinthu chomwe mukufuna chamitundu itatu. Chizindikiro cha nthawi yeniyeni ya makompyuta apamwamba chimaperekedwa ku goli lopatuka pambuyo pa kutembenuka kwa digito-to-analogi ndi kukulitsa mphamvu, ndipo mtengo wa electron umasokonekera pansi pa mphamvu ya maginito yopangidwa ndi magetsi osakanikirana kuti akwaniritse kusungunuka kosankha. Pambuyo pazaka zopitilira khumi zofufuza, zidapezeka kuti magawo ena amachitidwe monga ma elekitironi mtengo wapano, kuyang'ana pakalipano, nthawi yochitapo kanthu, makulidwe a ufa, kuthamanga kwamagetsi, ndi makina ojambulira amachitidwa pakuyesa kwa orthogonal. Nthawi yochitapo kanthu imakhala ndi chikoka chachikulu pakupanga.

Ubwino wakepa EBSM

Ukadaulo wopangira chitsulo chowongolera ma elekitironi umagwiritsa ntchito ma elekitironi amphamvu kwambiri ngati gwero la kutentha. Kupanga sikani kutha kuchitidwa popanda inertia yamakina pogwiritsira ntchito koyilo yokhotakhota maginito, ndipo malo opanda mpweya a mtengo wa elekitironi amathanso kuletsa ufa wachitsulo kuti usakhale oxidized panthawi yamadzimadzi kapena kusungunuka. Poyerekeza ndi laser, mtengo wa ma elekitironi uli ndi ubwino wogwiritsa ntchito mphamvu zambiri, kuya kwake kwakukulu, kuyamwa kwakukulu kwa zinthu, kukhazikika komanso kutsika mtengo ndi kukonza. Ubwino waukadaulo wa EBM umaphatikizira kupanga bwino kwambiri, kusinthika kwapang'onopang'ono, kusafunikira thandizo lachitsulo panthawi yopanga, denser microstructure, ndi zina zotero. Kupatuka kwa mtengo wa ma elekitironi ndikuwongolera kuyang'ana kumakhala kofulumira komanso kosavuta. Kupatuka kwa laser kumafuna kugwiritsa ntchito kalilole wonjenjemera, ndipo liwiro lozungulira la galasi logwedezeka limakhala lachangu kwambiri pomwe laser imayang'ana mothamanga kwambiri. Pamene mphamvu ya laser ikuwonjezeka, galvanometer imafuna dongosolo lozizira kwambiri, ndipo kulemera kwake kumawonjezeka kwambiri. Zotsatira zake, mukamagwiritsa ntchito kusanthula kwamphamvu kwambiri, kuthamanga kwa sikani ya laser kumakhala kochepa. Mukasanthula mitundu yayikulu yopangira, kusintha kutalika kwa laser kumakhala kovuta. Kupatuka ndi kuyang'ana kwa mtengo wa electron kumachitika ndi maginito. Kupindika ndi kuyang'ana kutalika kwa mtengo wa elekitironi kumatha kuwongoleredwa mwachangu komanso mwachidwi posintha mphamvu ndi njira ya chizindikiro chamagetsi. Dongosolo loyang'ana mtengo wa ma elekitironi silidzasokonezedwa ndi kutuluka kwachitsulo. Mukasungunula zitsulo ndi ma lasers ndi matabwa a ma elekitironi, nthunzi yachitsulo imafalikira ponseponse ndikupanga danga ndikuphimba pamwamba pa chinthu chilichonse chokhudzana ndi filimu yachitsulo. Kupotoza ndi kuyang'ana kwa matabwa a ma elekitironi onse amachitidwa mu mphamvu ya maginito, kotero iwo sangakhudzidwe ndi kutuluka kwachitsulo; Zipangizo zamagetsi monga laser galvanometers zimadetsedwa mosavuta ndi evaporation.

Laser Inetal Kuyika(LMD)

Laser Metal Deposition (LMD) idaperekedwa koyamba ndi Sandia National Laboratory ku United States m'ma 1990, kenako idapangidwa motsatizana m'madera ambiri padziko lapansi. Popeza mayunivesite ambiri ndi mabungwe amachita kafukufuku pawokha, ukadaulo uwu Pali mayina ambiri, ngakhale mayina sali ofanana, koma mfundo zawo ndizofanana. Pakapangidwe kameneka, ufa umasonkhanitsidwa pa ndege yogwira ntchito kudzera mumphuno, ndipo mtengo wa laser umasonkhanitsidwanso mpaka pano, ndipo mfundo za ufa ndi zowunikira zimangochitika mwangozi, ndipo chinthu chokhazikika chokhazikika chimapezeka podutsa pa tebulo kapena mphuno.

Tekinoloje ya LENS amagwiritsa ntchito kilowatt-class lasers. Chifukwa cha malo akuluakulu a laser, nthawi zambiri amapitilira 1mm, ngakhale zida zachitsulo zomangika mwazitsulo zimatha kupezeka, kulondola kwake komanso kutsirizika kwawo sikwabwino kwambiri, ndipo makina owonjezera amafunikira musanagwiritse ntchito. Laser cladding ndi zovuta thupi ndi mankhwala metallurgical ndondomeko, ndi magawo a ndondomeko cladding ndi chikoka chachikulu pa khalidwe la zobvala mbali. Njira zopangira laser cladding makamaka zimaphatikizira mphamvu ya laser, m'mimba mwake, kuchuluka kwa defocusing, kuthamanga kwa ufa, kuthamanga kwa sikani, kutentha kwa dziwe losungunuka, ndi zina zotere, zomwe zimakhudza kwambiri kuchuluka kwa dilution, ming'alu, kuwuma kwapamtunda komanso kuphatikizika kwa magawo ophimba. Panthawi imodzimodziyo, parameter iliyonse imakhudzanso wina ndi mzake, yomwe ndi njira yovuta kwambiri. Njira zowongolera zoyenera ziyenera kutsatiridwa kuti ziwongolere zinthu zosiyanasiyana zokopa mkati mwa njira zovomerezeka zotsekera.

ChindunjiMetal Laser Spakatindi(DMLS)

Nthawi zambiri pali njira ziwiriSLSkupanga mbali zachitsulo, imodzi ndi njira yosalunjika, ndiko kuti, SLS ya ufa wachitsulo wopangidwa ndi polima; winayo ndi njira yachindunji, ndiyo, Direct Metal Laser Sintering (DMLS) .Popeza kafukufuku wa laser sintering mwachindunji ufa zitsulo unachitikira pa Chatofci University Leuvne mu 1991, sintering mwachindunji ufa zitsulo kupanga magawo atatu azithunzithunzi ndi ndondomeko SLS ndi chimodzi mwa zolinga mtheradi wa prototyping mofulumira. Poyerekeza ndi ukadaulo wosalunjika wa SLS, mwayi waukulu wa njira ya DMLS ndikuchotsa njira zotsika mtengo komanso zowononga nthawi yayitali komanso njira zochiritsira.

Mawonekedwe pa DMLS

Monga nthambi yaukadaulo wa SLS, ukadaulo wa DMLS uli ndi mfundo yofanana. Komabe, ndizovuta kupanga molondola magawo achitsulo okhala ndi mawonekedwe ovuta ndiukadaulo wa DMLS. Pamapeto pake, makamaka chifukwa cha "spheroidization" zotsatira ndi sintering deformation ya ufa wachitsulo mu DMLS. Spheroidization ndi chodabwitsa chimene pamwamba mawonekedwe a chitsulo chosungunula madzi amasintha kwa ozungulira padziko pansi kumavuta interfacial pakati pa madzi zitsulo ndi ozungulira sing'anga kuti dongosolo wapangidwa pamwamba pa chitsulo chosungunula madzi ndi pamwamba ozungulira sing'anga ndi osachepera ufulu mphamvu. Spheroidization imapangitsa kuti ufa wachitsulo sungathe kulimba pambuyo posungunuka kuti ukhale dziwe losungunuka lopitirira komanso losalala, kotero kuti zigawo zomwe zimapangidwa zimakhala zotayirira komanso zowonongeka, zomwe zimapangitsa kuti kuumba kulephera. Chifukwa cha kukhuthala kwakukulu kwa gawo limodzi la chitsulo mu gawo lamadzimadzi la sintering, "spheroidization" kwenikweni ndi yayikulu kwambiri, ndipo m'mimba mwake imakhala yokulirapo kuposa m'mimba mwake mwa tinthu tating'onoting'ono tating'onoting'ono, zomwe zimatsogolera ku pores ambiri m'magawo a sintered. Choncho, DMLS ya ufa wachitsulo umodzi uli ndi zolakwika zoonekeratu, ndipo nthawi zambiri zimafuna chithandizo chotsatira, osati tanthauzo lenileni la "sintering mwachindunji".

Pofuna kuthana ndi "spheroidization" chodabwitsa cha chigawo chimodzi zitsulo ufa DMLS ndi chifukwa ndondomeko kupunduka monga sintering mapindikidwe ndi lotayirira kachulukidwe, akhoza zambiri zimatheka pogwiritsa ntchito Mipikisano chigawo ufa zitsulo ndi mfundo kusungunuka osiyana kapena ntchito chisanadze alloying ufa. Dongosolo la ufa wazitsulo wamitundu yambiri nthawi zambiri limapangidwa ndi zitsulo zosungunuka kwambiri, zitsulo zotsika kwambiri zosungunuka ndi zina zowonjezera. Ufa wachitsulo wosungunuka kwambiri monga chitsulo chosungunuka chimatha kusunga maziko ake olimba mu DMLS. The otsika osungunuka mfundo zitsulo ufa ntchito ngati binder zitsulo, amene anasungunuka mu DMLS kupanga madzi gawo, ndi chifukwa madzi gawo malaya, wets ndi zomangira olimba gawo zitsulo particles kukwaniritsa sintering kachulukidwe.

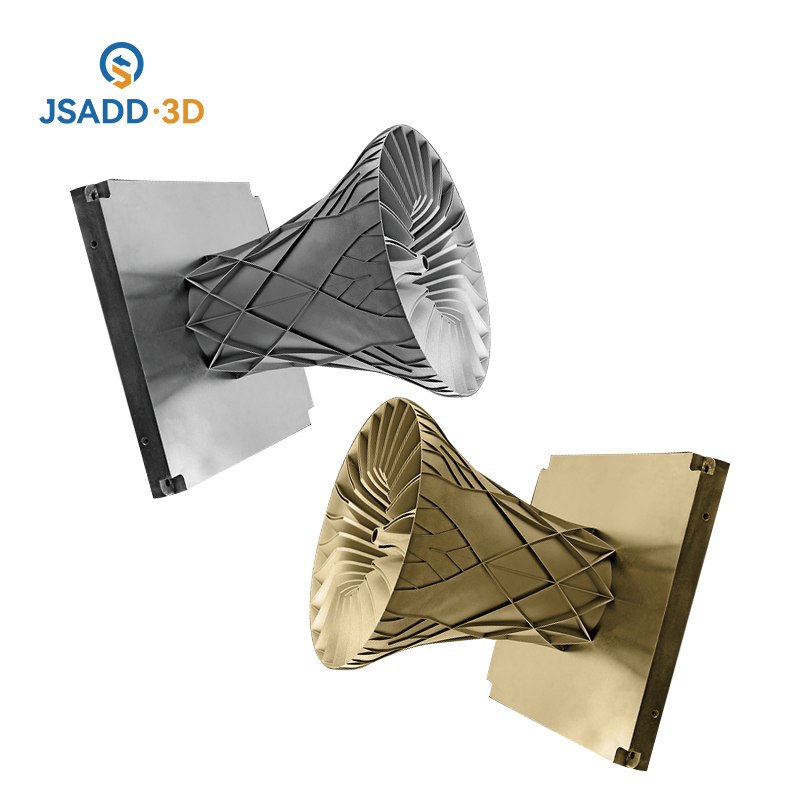

Monga kampani yayikulu ku ChinaNtchito yosindikiza ya 3Dmafakitale,JSADD3D sidzaiwala cholinga chake choyambirira, kuonjezera ndalama, kuyambitsa ndi kupanga matekinoloje ambiri, ndikukhulupirira kuti idzabweretsa chidziwitso chatsopano cha 3D kwa anthu.

Wothandizira: Sammi