Electron Beam hehee(EBM)

Electron Beam Selective Melting (EBSM) Kumukānāwai

E like me ka laser selective sintering aHoohehee Laser waeʻO nā kaʻina hana, electron beam selective melting technology (EBSM) he ʻenehana hana wikiwiki e hoʻohana ana i nā kaola electron kiʻekiʻe a me ka wikiwiki e koho i ka pahu metala, a laila hoʻoheheʻe a hana i nā mea pauka.

ʻO ke kaʻina hana o EBSM ʻo ka ʻenehana penei: ʻo ka mua, e hohola i kahi papa lepo ma luna o ka mokulele palahalaha; a laila, ma lalo o ka lolouila mana, ka electron kukuna ua selectively hehee ai e like me ka ike o ka cross-sectional profile, a me ka pauka metala ua hehee pu, paa me ka mea i hoʻokumu 'ia ma lalo, a ahu iho la ma ka papa a hiki i ka hapa a pau i hehee ai; ʻO ka hope, hoʻoneʻe ʻia ka pauda keu e hāʻawi i ka huahana ʻekolu-dimensional i makemake ʻia. Hoʻouna ʻia ka hōʻailona scanning manawa maoli o ka lolouila luna i ka ʻauamo deflection ma hope o ka hoʻololi ʻana i ka digital-to-analog a me ka hoʻonui ʻana i ka mana, a ua hoʻohuli ʻia ka kukuna electron ma lalo o ka hana o ke kahua magnetic i hoʻokumu ʻia e ka volta deflection pili e hoʻokō i ka hehee koho. Ma hope o ʻumi makahiki o ka noiʻi ʻana, ʻike ʻia kekahi mau kaʻina hana e like me ka electron beam current, ka nānā ʻana i kēia manawa, ka manawa hana, ka mānoanoa o ka pauka, ka wikiwiki a me ke ʻano scanning i nā hoʻokolohua orthogonal. ʻO ka manawa hana ka mea nui loa i ka hoʻokumu ʻana.

Nā ponoo EBSM

Electron beam direct metal forming technology ho'ohana i ka ikehu ki'eki'e electron beam e like me ke kumu wela. Hiki ke hana ʻia ka hana scanning me ka ʻole o ka mechanical inertia ma o ka hoʻohana ʻana i ka coil deflection magnetic, a hiki i ke kaiapuni vacuum o ka electron beam ke pale aku i ka pauka metala mai ka hoʻoneʻe ʻia ʻana i ka wā o ka hoʻoheheʻe ʻana a me ka hoʻoheheʻe ʻana. Ke hoʻohālikelike ʻia me ka laser, loaʻa i ka electron beam nā mea maikaʻi o ka nui o ka hoʻohana ʻana i ka ikehu, ka hohonu hana nui, ka nui o ka absorption material kiʻekiʻe, ke kūpaʻa a me ka haʻahaʻa o ka hana a me nā kumukūʻai mālama. ʻO nā pōmaikaʻi o ka ʻenehana EBM e pili ana i ka hana kiʻekiʻe, ka haʻahaʻa haʻahaʻa deformation, ʻaʻohe pono o ke kākoʻo metala i ka wā o ke kaʻina hana, microstructure denser, a pēlā aku. ʻOi aku ka wikiwiki a ʻoi aku ka maʻalahi o ka deflection beam electron a me ka mana o ka manaʻo. Pono ka hoʻololi ʻana o ka laser i ka hoʻohana ʻana i ke aniani haʻalulu, a ʻo ka wikiwiki o ka ʻōwili ʻana o ke aniani haʻalulu he wikiwiki loa ke nānā ka laser i nā wikiwiki kiʻekiʻe. Ke hoʻonui ʻia ka mana laser, pono ka galvanometer i kahi ʻōnaehana hoʻoluʻu paʻakikī, a piʻi nui kona kaumaha. ʻO ka hopena, i ka wā e hoʻohana ai i ka nānā ʻana i ka mana kiʻekiʻe, e kaupalena ʻia ka wikiwiki o ka nānā ʻana o ka laser. I ka nānā ʻana i kahi ʻano hana nui, paʻakikī hoʻi ka hoʻololi ʻana i ka lōʻihi kiko o ka laser. Hoʻokō ʻia ka deflection a me ka nānā ʻana o ka kukuna electron e ke kahua magnetic. Hiki ke ho'omalu 'ia ka lō'ihi a me ka nānā 'ana o ke kukuna electron ma o ka ho'ololi 'ana i ka ikaika a me ke kuhikuhi o ka hō'ailona uila. ʻAʻole e hoʻopilikia ʻia ka ʻōnaehana hoʻokele electron beam e ka hoʻoheheʻe metala. I ka hoʻoheheʻe ʻana i ka metala me nā lasers a me nā kukuna electron, e laha ʻia ka mahu metala a puni ka lumi hana a uhi i ka ʻili o kekahi mea i hoʻopili ʻia me kahi kiʻiʻoniʻoni metala. ʻO ka hoʻohuli ʻana a me ka nānā ʻana o nā kukuna electron i hana ʻia i loko o kahi māla magnetic, no laila ʻaʻole lākou e hoʻopilikia ʻia e ka evaporation metala; ʻO nā mea optical e like me ka laser galvanometers ua maʻalahi ka haumia e ka evaporation.

Laser Metal Waihona(LMD)

ʻO Laser Metal Deposition (LMD) i hoʻopuka mua ʻia e Sandia National Laboratory ma ʻAmelika Hui Pū ʻIa i ka makahiki 1990, a laila hoʻomohala holomua ma nā wahi he nui o ka honua. No ka mea he nui nā kulanui a me nā ʻoihana e hana i ka noiʻi kūʻokoʻa, ʻo kēia ʻenehana He nui nā inoa, ʻoiai ʻaʻole like nā inoa, akā ʻo kā lākou mau loina ka mea like. I ka wā o ke kaʻina hana, e hōʻiliʻili ʻia ka pauka ma ka mokulele hana ma o ka nozzle, a ua hōʻiliʻili pū ʻia ka kukuna laser a hiki i kēia manawa, a ʻokoʻa ka pauka a me nā wahi hana māmā, a loaʻa ka mea i hoʻopaʻa ʻia ma ka neʻe ʻana i ka papa hana a i ʻole nozzle.

ʻenehana LENS hoʻohana i nā lasers kilowatt-class. Ma muli o ke kikowaena laser nui, ʻoi aku ka nui ma mua o 1mm, ʻoiai hiki ke loaʻa i nā mea metala paʻa i hoʻopaʻa ʻia me ka metallurgically, ʻaʻole maikaʻi loa kā lākou dimensional pololei a me ka hoʻopau ʻana o ka ʻili, a koi ʻia ka mīkini hou ma mua o ka hoʻohana ʻana. ʻO ka hoʻopaʻa ʻana laser he mea paʻakikī i ke kino a me ke kemika metala, a ʻo nā ʻāpana o ke kaʻina pale i ka hopena nui i ka maikaʻi o nā ʻāpana lole. ʻO nā ʻāpana kaʻina hana i ka laser cladding ka nui o ka mana laser, ke anawaena wahi, ka nui defocusing, ka wikiwiki ʻai ʻana i ka pauka, ka wikiwiki scanning, ka mahana wai hoʻoheheʻe ʻia, a me nā mea ʻē aʻe, he hopena nui i ka dilution rate, crack, surface roughness and compactness of cladding parts. I ka manawa like, pili pū kēlā me kēia ʻāpana i kekahi i kekahi, kahi hana paʻakikī loa. Pono e hoʻohana ʻia nā ʻano hoʻomalu kūpono e hoʻomalu i nā mea hoʻoikaika like ʻole i loko o ka laulā ʻae o ke kaʻina hana cladding.

pololeiMetala Laser Swaenaana(DMLS)

ʻElua mau ala maʻamau noSLSno ka hana ʻana i nā ʻāpana metala, ʻo ia ke ʻano hana ʻole, ʻo ia hoʻi, SLS o ka pauka metala polimer-coated; ʻO ka mea ʻē aʻe ke ala pololei, ʻo ia hoʻi, Direct Metal Laser Sintering (DMLS). Mai ka noiʻi ʻana i ka sintering laser pololei o ka pauka metala i lawe ʻia ma ke Kulanui ʻo Chatofci ma Leuvne ma 1991, ʻo ka sintering pololei o ka pauka metala e hana i nā ʻāpana ʻekolu-dimensional e ke kaʻina SLS kekahi o nā pahuhopu hope loa o ka prototyping wikiwiki. Ke hoʻohālikelike ʻia me ka ʻenehana SLS indirect, ʻo ka pōmaikaʻi nui o ka kaʻina DMLS ʻo ka hoʻopau ʻana i nā kaʻina hana ma mua o ka mālama ʻana a me ka manawa.

Nā hiʻohiʻona o DMLS

Ma ke ʻano he lālā o ka ʻenehana SLS, ʻo ka ʻenehana DMLS ke kumu like. Eia naʻe, paʻakikī ke hana pololei i nā ʻāpana metala me nā ʻano paʻakikī e ka ʻenehana DMLS. I ka hopena hope loa, ma muli o ka hopena "spheroidization" a me ka sintering deformation o ka pauka metala ma DMLS. ʻO ka Spheroidization kahi mea e hoʻololi ai ka ʻili o ka wai metala i hoʻoheheʻe ʻia i ka ʻili spherical ma lalo o ka haʻalulu ma waena o ka metala wai a me ke ʻano a puni i mea e hana ai ka ʻōnaehana i ka ʻili o ka wai hoʻoheheʻe ʻia a me ka ʻili o ka mea a puni me ka liʻiliʻi o ka ikehu manuahi. ʻO ka Spheroidization ka mea hiki ʻole ke paʻa i ka pauka metala ma hope o ka hoʻoheheʻe ʻana e hana i ka wai hoʻoheheʻe hoʻomau a maʻemaʻe, no laila ua wehe a porous nā ʻāpana i hana ʻia, e hopena ai i ka pau ʻole o ka hana ʻana. Ma muli o ka viscosity kiʻekiʻe o ka pauka metala hoʻokahi i loko o ka pae sintering pae wai, ʻoi aku ka koʻikoʻi o ka hopena "spheroidization", a ʻoi aku ka nui o ke anawaena spherical ma mua o ke anawaena o nā ʻāpana pauka, e alakaʻi ana i ka nui o nā pores i nā ʻāpana sintered. No laila, ʻo ka DMLS o ka pauka metala mea hoʻokahi he mau hemahema kaʻina hana, a koi pinepine i ka mālama ʻana ma hope, ʻaʻole ke ʻano maoli o ka "sintering pololei".

I mea e lanakila ai i ka hanana "spheroidization" o ka pauka metala hoʻokahi DMLS a me ka hopena o nā hemahema e like me ka sintering deformation a me ka loose density, hiki ke hoʻokō maʻamau me ka hoʻohana ʻana i nā pauka metala me nā wahi heheʻe ʻokoʻa a i ʻole ka hoʻohana ʻana i nā pauka pre-alloying. Hoʻokumu ʻia ka ʻōnaehana pauka metala nui me nā metala hoʻoheheʻe kiʻekiʻe, nā metala hoʻoheheʻe haʻahaʻa a me kekahi mau mea hoʻohui. ʻO ka pauka metala metala kiʻekiʻe e like me ka metala iwi hiki ke hoʻopaʻa i kona kumu paʻa i DMLS. Hoʻohana ʻia ka pauka metala haʻahaʻa haʻahaʻa ma ke ʻano he metala binder, i hoʻoheheʻe ʻia i DMLS e hana i kahi ʻano wai, a ʻo ka hopena o ka pae wai e uhi ai, pulu a hoʻopaʻa i nā ʻāpana metala paʻa e hoʻokō ai i ka densification sintering.

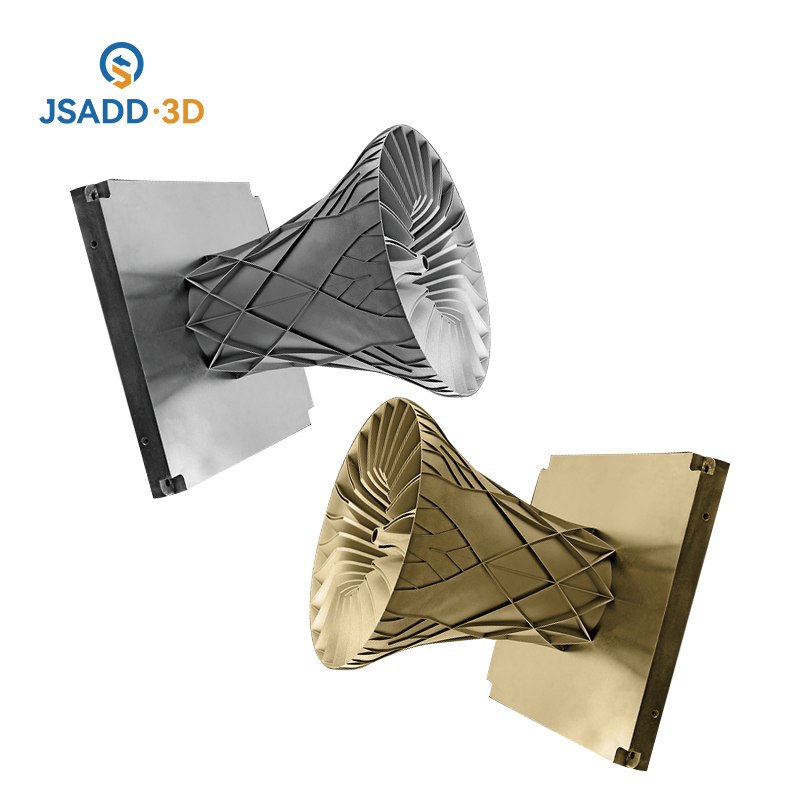

Ma ke ʻano he hui alakaʻi ma Kinalawelawe paʻi 3Dʻoihana,JSADD3D ʻaʻole e poina i kona manaʻo kumu, hoʻonui i ka hoʻopukapuka, hoʻomohala a hoʻomohala i nā ʻenehana hou aʻe, a manaʻoʻiʻo e lawe mai ia i ka ʻike paʻi 3D hou i ka lehulehu.

Mea kōkua: Sammi