Challenges of Traditional Craftsmanship in Automotive Manufacturing:

1.Complexity in Design and Precision: Automotive manufacturing requires precise and complex designs, especially for parts that need to meet strict safety and performance standards. Traditional methods often face challenges in achieving such precision consistently, especially for intricate components.

2.Time-Consuming: Traditional manufacturing methods, like casting, machining, and assembling, can be very time-consuming. The process of prototyping, testing, and then refining the designs adds to the production time, slowing down the overall manufacturing cycle.

3.High Costs: The tools, molds, and labor required for traditional automotive manufacturing can be expensive. Producing small batches of parts or prototypes is particularly costly because of the need for specialized equipment and processes.

Advantages of Using 3D Printing in Automotive Manufacturing:

1.Design Flexibility and Customization: 3D printing allows for the creation of highly customized and complex parts that may not be feasible with traditional manufacturing. This is particularly beneficial for creating prototypes or low-volume custom components, allowing for faster iterations and design changes.

2.Cost-Effective Prototyping: 3D printing reduces the costs associated with prototyping. Unlike traditional methods that require expensive molds and tooling, 3D printing can produce prototypes directly from digital models at a fraction of the cost.

3.Faster Production and Reduced Lead Time: 3D printing enables rapid prototyping and manufacturing, significantly shortening the time required to produce parts. This allows for quicker testing, iteration, and delivery, which is particularly important in the fast-paced automotive industry.

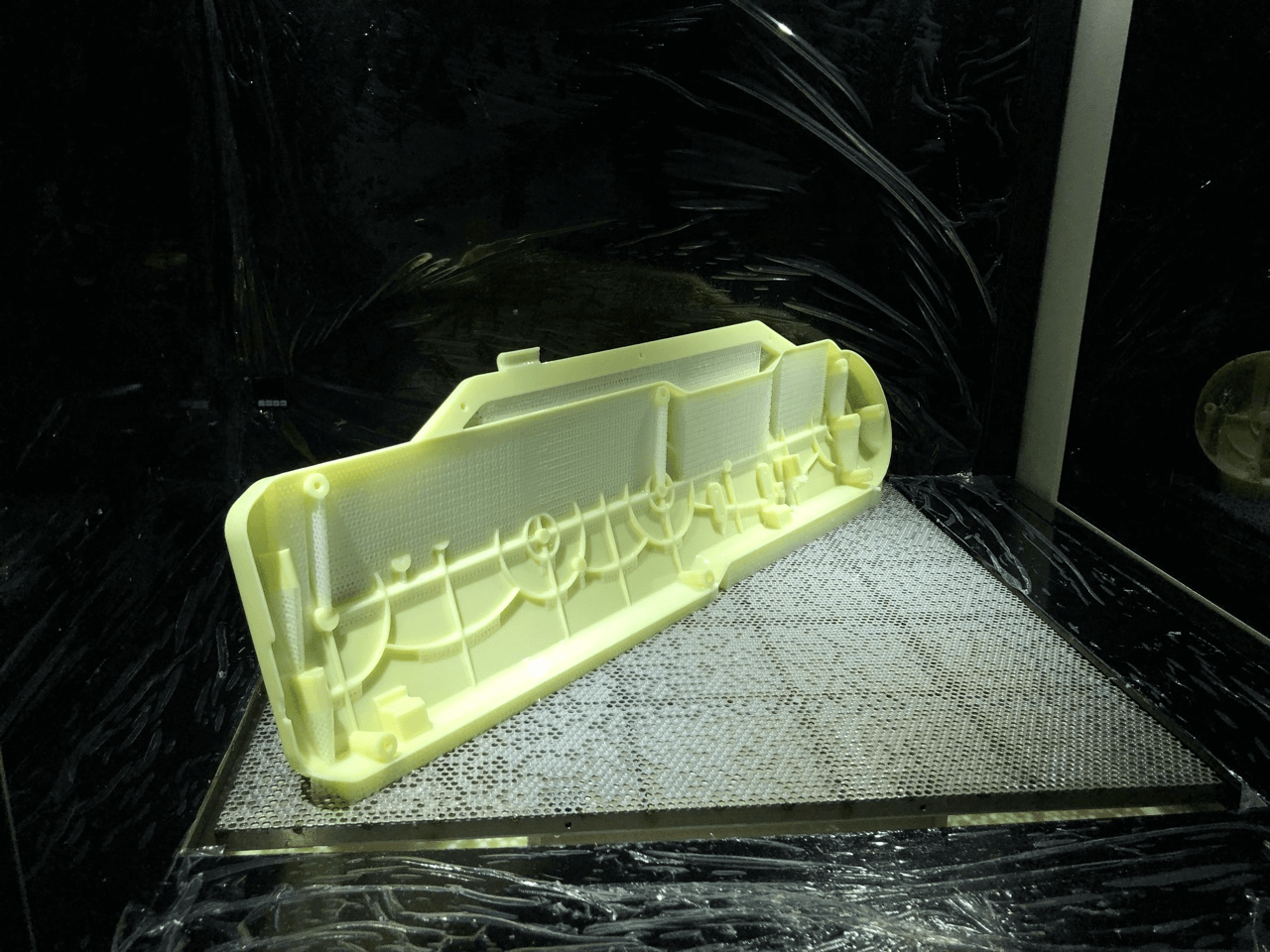

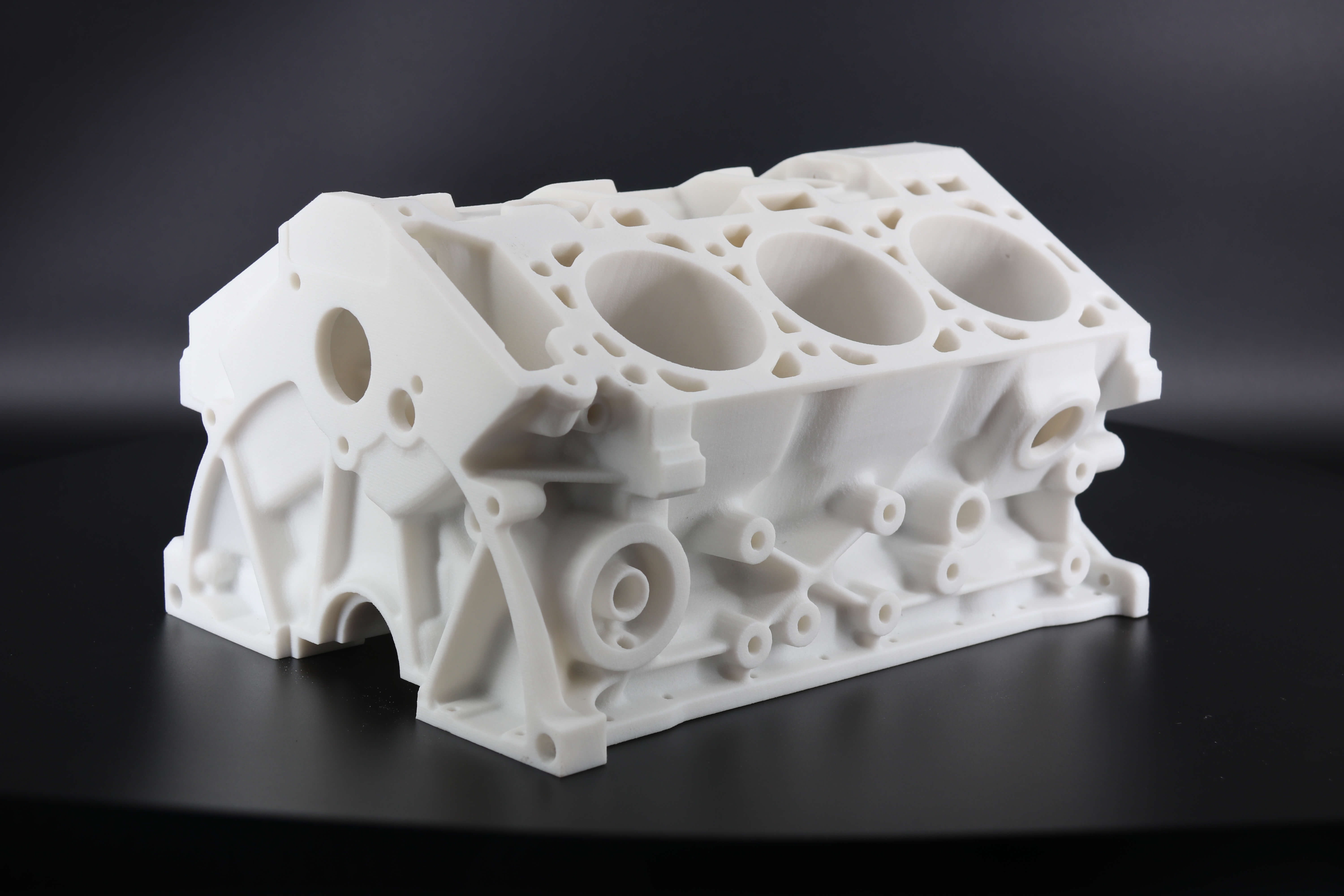

SLA Technology

SLA (Stereolithography) 3D printing offers high precision and smooth surface finishes, making it ideal for producing detailed automotive prototypes and complex parts. It enables rapid iteration and customization, helping speed up design validation and reduce development costs. SLA’s ability to create intricate geometries supports lightweight and functional components in automotive manufacturing.

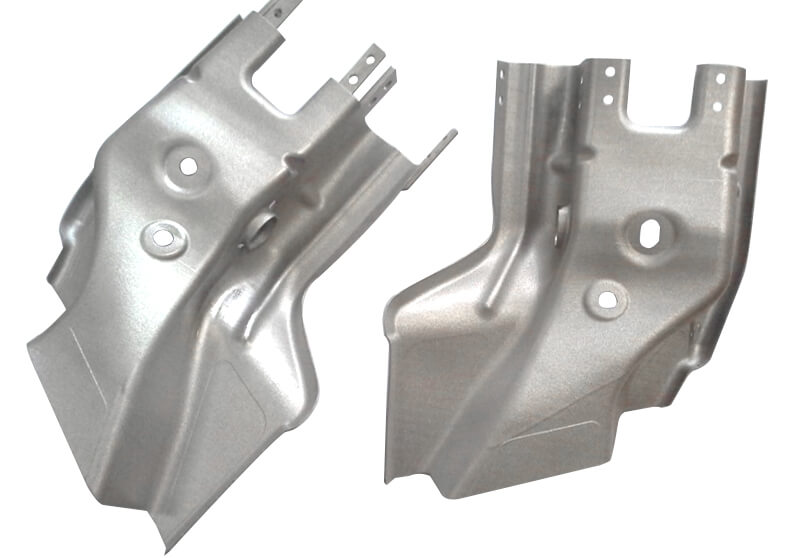

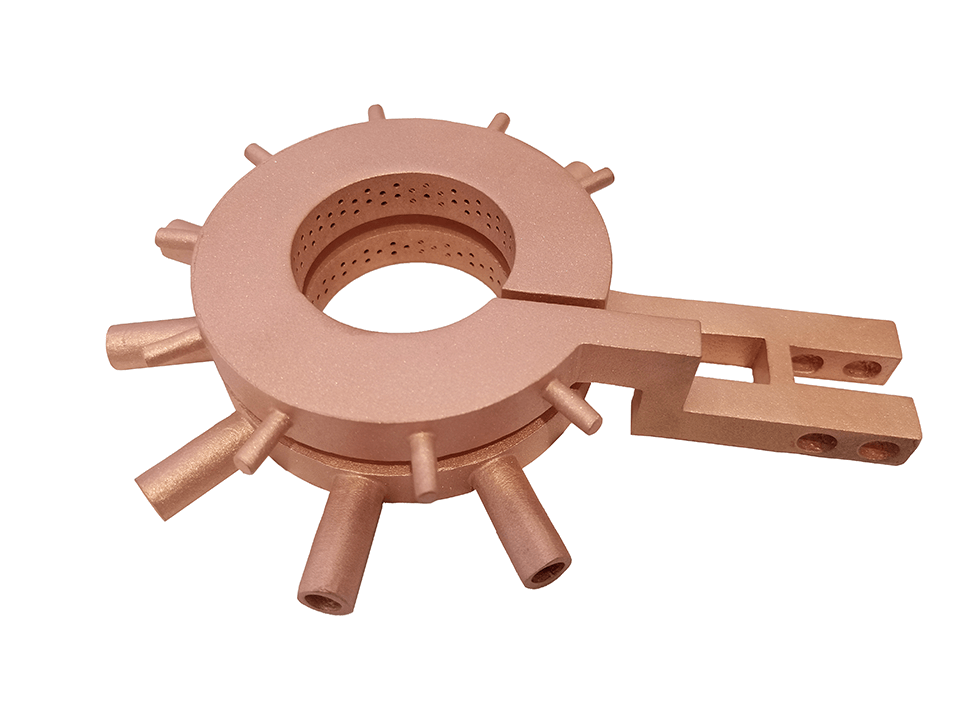

SLM Technology

SLM (Selective Laser Melting) 3D printing is highly beneficial for automotive manufacturing as it allows for the creation of strong, lightweight, and complex metal components. It offers high precision and design flexibility, enabling the production of optimized parts that improve performance and reduce material waste. SLM also supports rapid prototyping, reducing development time and costs while ensuring high-quality, durable automotive components.

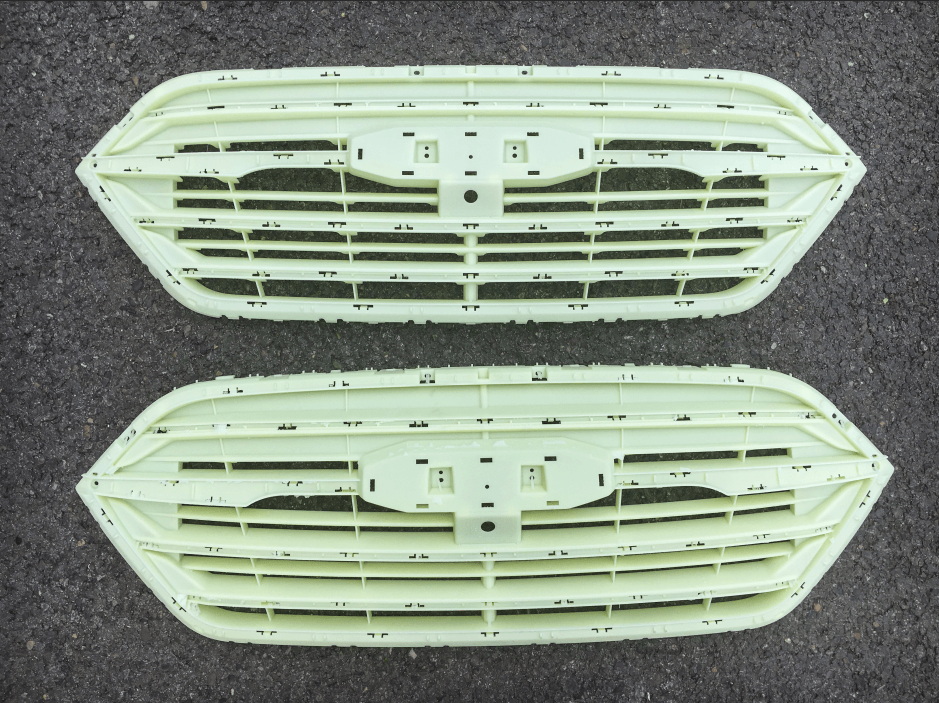

SLS Technology

SLS (Selective Laser Sintering) 3D printing is ideal for automotive manufacturing as it can create durable, functional parts with complex geometries using a variety of materials, including plastics and metals. It offers high design flexibility, allowing for lightweight, custom components that optimize performance. SLS also supports rapid prototyping and small-batch production, reducing lead times and costs in the automotive industry.

If you' re interested in learning more about the applications of 3D printing feel free to Click Inquiry Now